What is a SLA 3D printer?

The SLA 3D printer is a 3D printer that uses light curing technology. It uses ultraviolet laser or LED light source to irradiate the liquid photosensitive resin to make it solidify so as to realize the construction of the object. Specifically, the

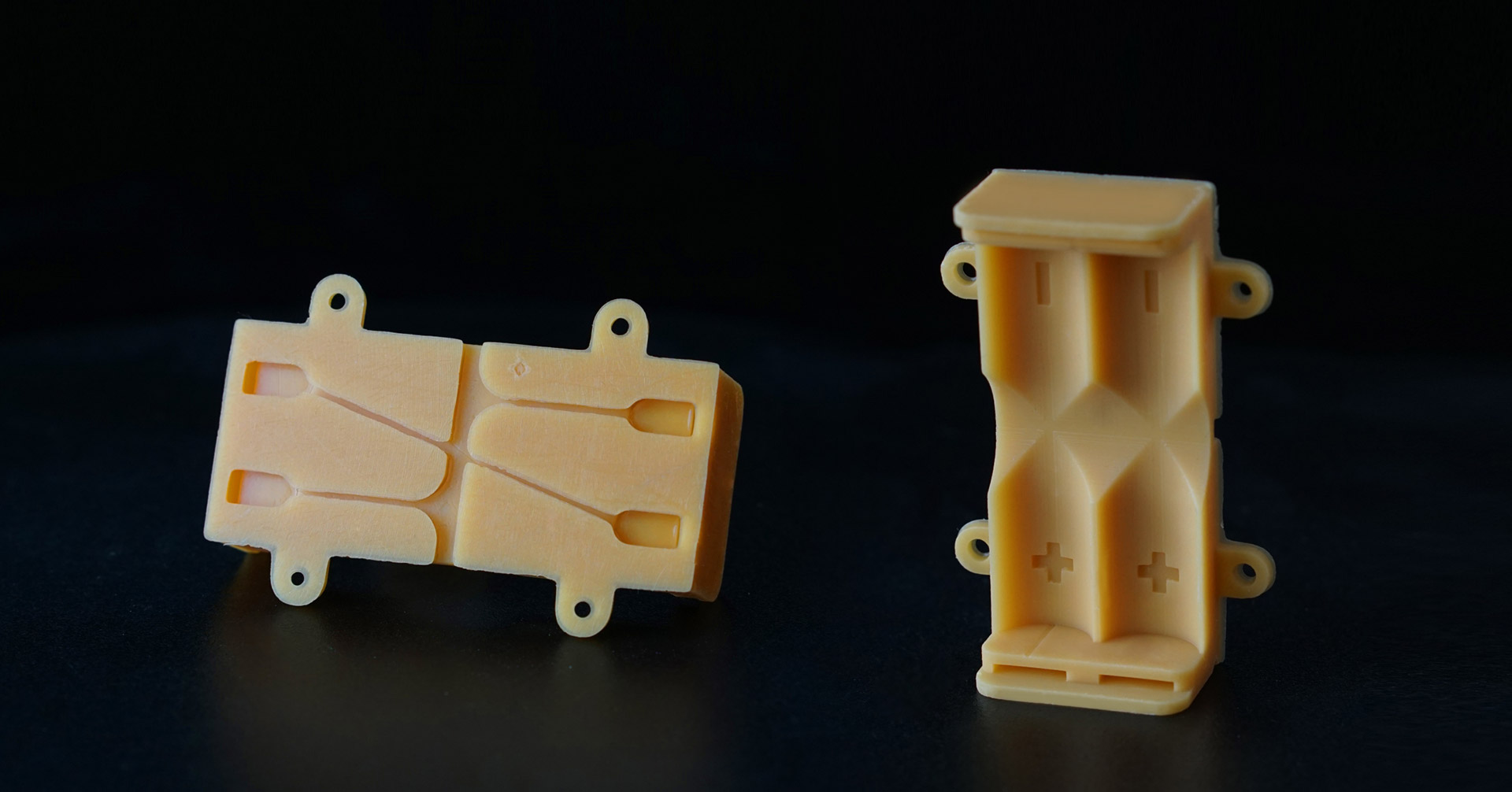

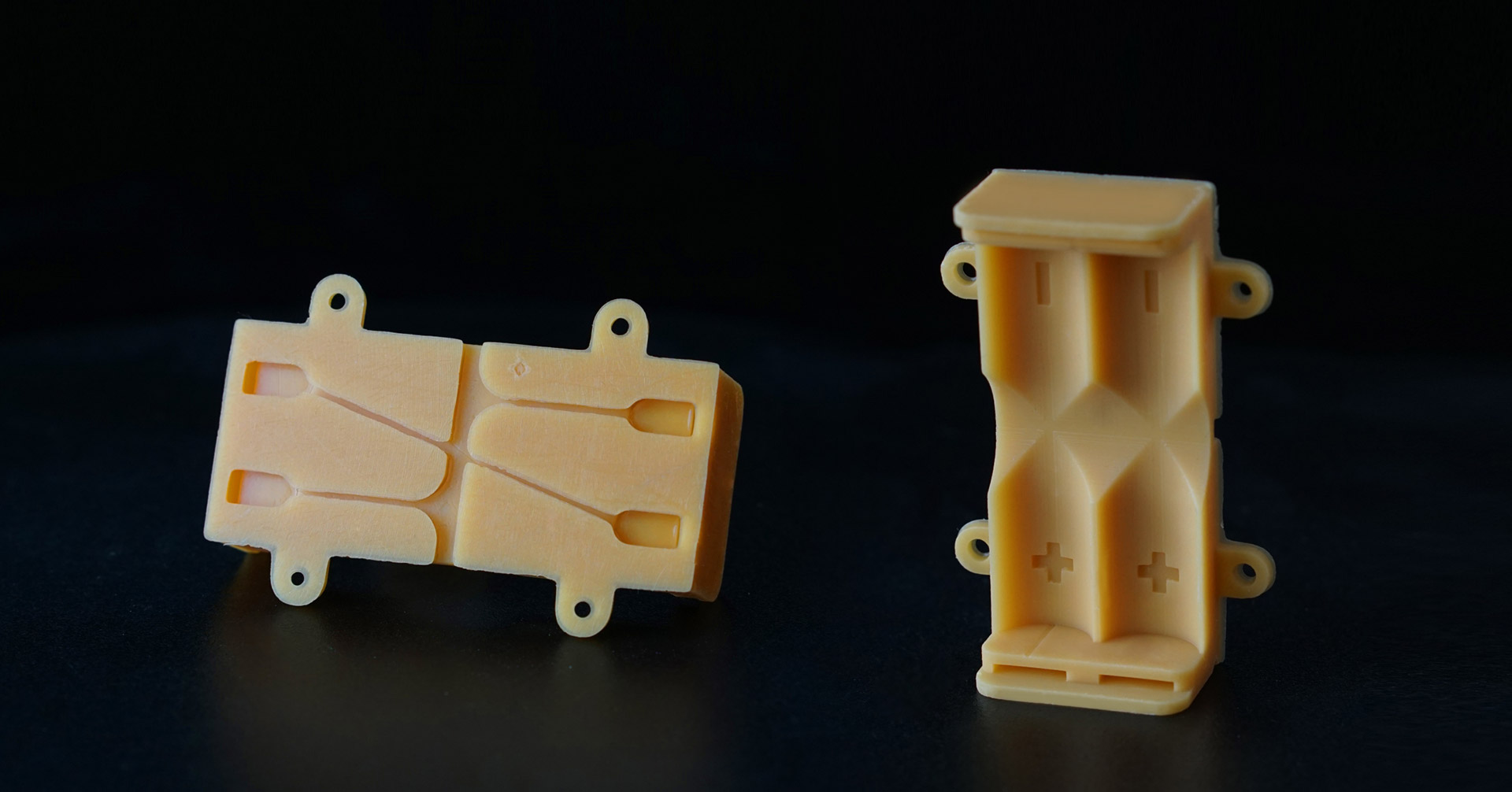

SLA 3D printer solidifies the liquid photosensitive resin layer by layer to form a solid model by controlling the position and intensity of the laser/light source. This printing technology can produce very fine and complex parts and models, so it is widely used in jewelry, medical, automotive, industrial design and other fields.

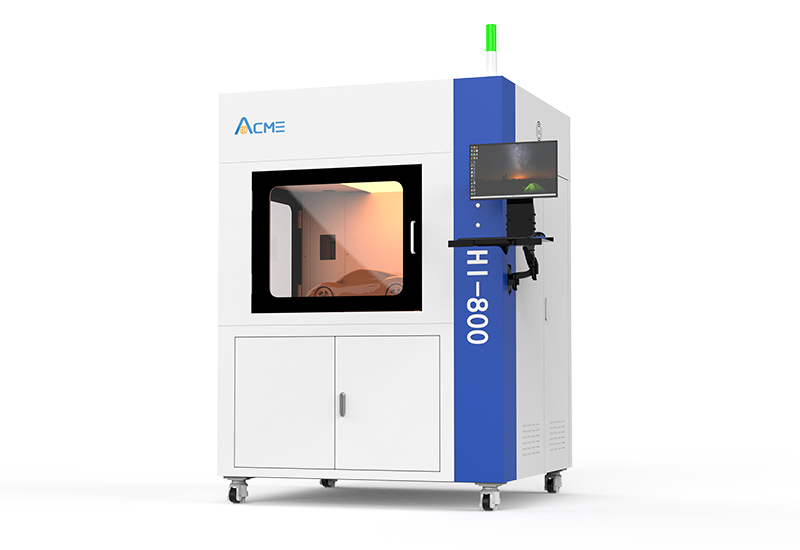

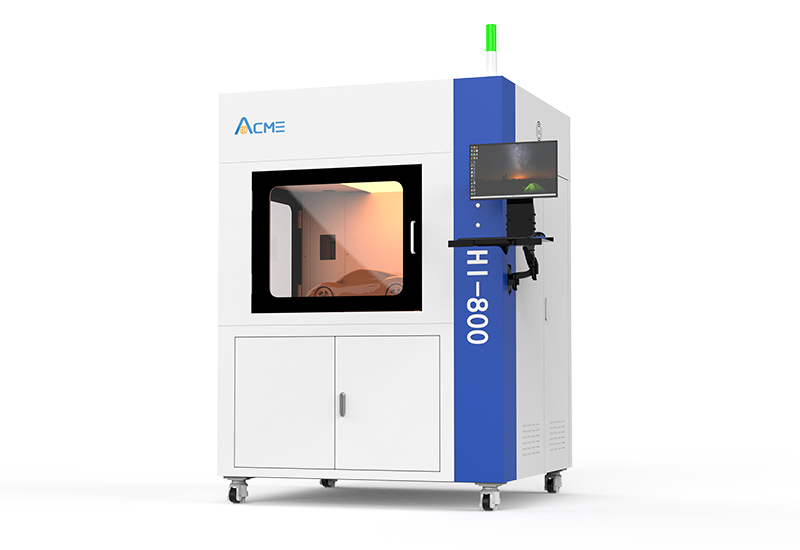

How does the SLA 3D printer work? Let's take ACME Engineering 3D SLA 3D printer HI800 as an example:

ACME Engineering 3D SLA 3D printer HI800 uses light-curing 3D printing technology. Its working principle is: import the designed 3D model file to the control software of the printer through the 3D modeling software, slice and path-plan the model according to the shape and size to be printed, and form dozens to hundreds of layers of slices data. Next, the control software transmits the slicing data to the printer, and the printer analyzes it and projects UV laser beams on the surface of the liquid photosensitive resin layer by layer through the lens to solidify it into a solid model under the action of light. Finally, the uncured resin solution is removed, and the cured model is cleaned and post-processed to obtain the desired 3D printed product.

The forming principle of ACME Engineering 3D industrial-grade SLA 3D printer HI800 is similar to that of general light-curing 3D printers, mainly divided into the following steps:

1. Modeling: Create models using CAD or other 3D modeling software.

2. Slicing: Divide the model into multi-layer slices and generate corresponding slice data.

3. Forming preparation: Position the printing platform to the initial position, apply a layer of photosensitive resin suitable for forming, and start pre-irradiation.

4. Printing: The printing platform is lowered layer by layer, and the laser or LED light source irradiates the resin coating to partially solidify it into a layer of the model.

5. Coating: Apply a new layer of resin and repeat the above steps until the model is printed.

6. Cleaning: Take the printed model out of the printer, and wash off excess resin coating with cleaning solution.

7. Post-processing: After the cleaned model is dried, light-cured, polished, painted and other post-processing steps, the finished product is finally obtained.

ACME Engineering 3D industrial-grade

SLA 3D printer HI800 cures the coating resin layer by layer through laser or LED light source, and the light curing method is the polymerization and curing of photosensitive resin caused by ultraviolet radiation, while the unirradiated resin remains in a fluid state, thus The molding process is realized. Compared with traditional manufacturing methods, SLA 3D printers have the advantages of high speed, high precision, and strong customizability, so they are widely used in many fields.