Industrial-grade 3D printers are widely used in casting processes. Among them, the main application is the manufacture of foundry molds and castings. The manufacturing process of traditional casting molds and cores takes a lot of time and effort, while

industrial-grade 3D printers can manufacture high-quality, high-complexity molds and cores in a short period of time. This not only increases production efficiency, but also reduces errors and waste during mold making. In addition, industrial-grade 3D printers can also create complex parts and assemblies that can be used in automotive, aviation, aerospace and other fields. Due to the high precision and high efficiency of industrial-grade 3D printers, more and more foundry companies have begun to adopt this technology to improve their production efficiency and quality.

3D printers are increasingly used in casting processes, including rapid production of molds, molds and complex castings. Specifically, it can help foundry companies realize the following advantages:

1: Quickly make molds and molds: 3D printing technology can quickly make molds and molds, reduce the time and cost of traditional molds and molds, and improve production efficiency.

2: Flexibility: 3D printing technology can easily make complex castings through CAD design. It allows designers to design and modify more flexibly, resulting in faster, more creative and more customized production.

3: Saving materials: Through 3D printing technology, the amount of materials can be precisely controlled, reducing waste and reducing costs.

4: Reduce manpower: The traditional casting process requires a lot of manpower for manual production, while 3D printing can automate manufacturing, thereby reducing the need for manpower and improving production efficiency and manufacturing consistency.

In short, the application of 3D printing technology in the casting process has brought many changes to the traditional casting industry, making it more flexible and productive.

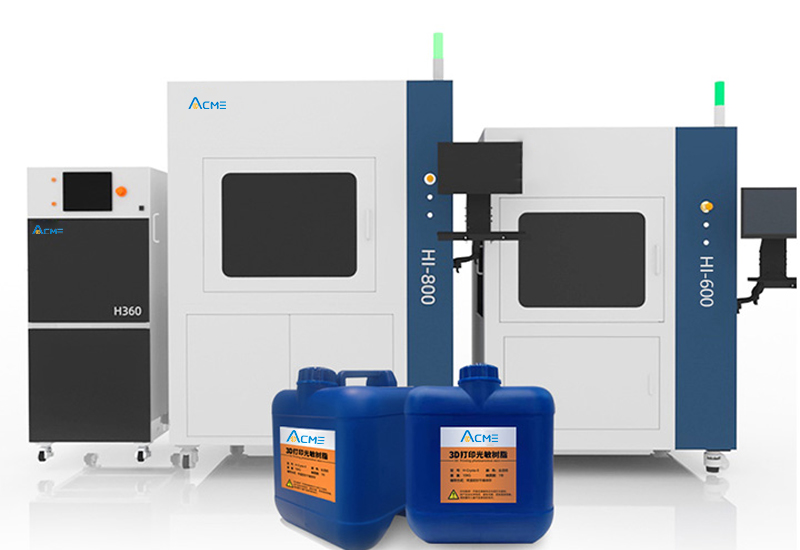

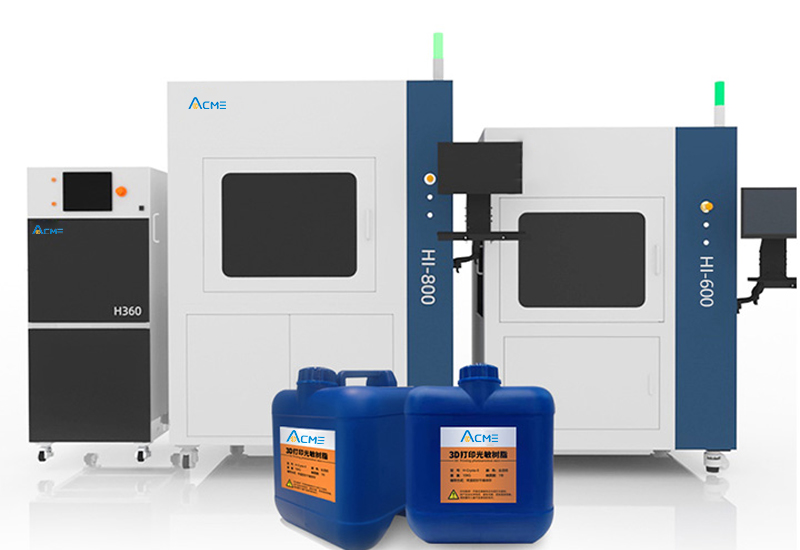

industrial-grade SLA series

industrial-grade SLA seriesACME 3D printers can be used in the casting process to make casting molds, casting cores, casting auxiliary tools, etc. 3D printing can quickly produce complex-shaped molds and cores, and can achieve high-precision, high-stability, and high-efficiency production. At the same time, 3D printing can also realize rapid customized production, and customize production according to different customer needs, improving production efficiency and production quality. ACME industrial-grade 3D printers have the characteristics of high precision, high stability, and high efficiency, which can meet the high requirements of the foundry industry.

industrial-grade SLA series

industrial-grade SLA series