Exploring industrial-grade 3D printers: a comprehensive analysis from technology to application

With the continuous development of 3D printing technology, 3D printers have gradually entered the home and personal markets from the high-end field. But at the same time, the demand for industrial-grade 3D printers is also increasing.

Industrial-grade 3D printers have higher precision, larger modeling range, stronger material adaptability and more scalability. This article will comprehensively explore industrial-grade 3D printers from two aspects of technology and application.

1. Technical analysis

1. Technical analysisThe technology of industrial 3D printers includes printing technology, material technology, control system and so on. At present, the main printing technologies on the market are SLA, SLS, FDM and DLP. Different printing technologies have their own characteristics and scope of application, and users need to choose different technologies according to specific needs.

SLA 3D printing technology is a rapid prototyping technology that uses laser or ultraviolet light to irradiate liquid photosensitive resin and solidify layer by layer to print out 3D objects. It has the advantages of high precision, smooth surface, fast forming speed, etc., and is widely used in hand-board making, jewelry making, medical equipment, artwork making and other fields.

SLS is a common 3D printing technology that uses laser beams to irradiate powder materials to melt and solidify layer by layer to become 3D printed parts. Compared with traditional SLA or FDM technology, SLS can print more complex and structurally strong parts, without the need for support structures, and can use a variety of materials. SLS printers are suitable for manufacturing industrial parts, shoe soles, aerospace components and many other fields.

FDM is a common 3D printing technology that uses thermoplastic materials to build a 3D printed model by ejecting the material from the print head and melting it through heat, stacking it layer by layer. FDM printer is one of the most common types of 3D printers at present. It is easy to use and low in cost. It is suitable for making 3D printing models of some simple structures, such as component prototypes, mechanical parts, toys, etc.

DLP is a 3D printing technology that uses liquid photosensitive resin materials. It uses a digital light processor to decompose a model image into layers and project it onto the liquid photosensitive resin, which is cured into a solid model by photocuring. DLP printing technology has high precision, high speed and good surface quality, which is suitable for producing fine and complex models and parts.

In terms of materials, the types of materials that can be used by industrial-grade 3D printers are more diverse, including plastics, metals, ceramics, and composite materials. At the same time, the control system of industrial-grade 3D printers is more sophisticated, and can control parameters such as temperature, speed, and pressure to achieve higher printing accuracy and quality.

2. Application analysisIndustrial-grade 3D printers are widely used in medical, aviation, automotive, industrial design and other fields. In the medical field, industrial-grade 3D printers can print high-precision models of human organs to assist in surgical simulation and medical research. In the field of aviation, industrial-grade 3D printers can print high-precision parts to improve the performance and safety of aviation components. In the automotive field, industrial-grade 3D printers can print complex parts to improve vehicle performance and safety. In the field of industrial design, industrial-grade 3D printers can help designers quickly prototype, shorten the design cycle, and improve product quality and production efficiency.

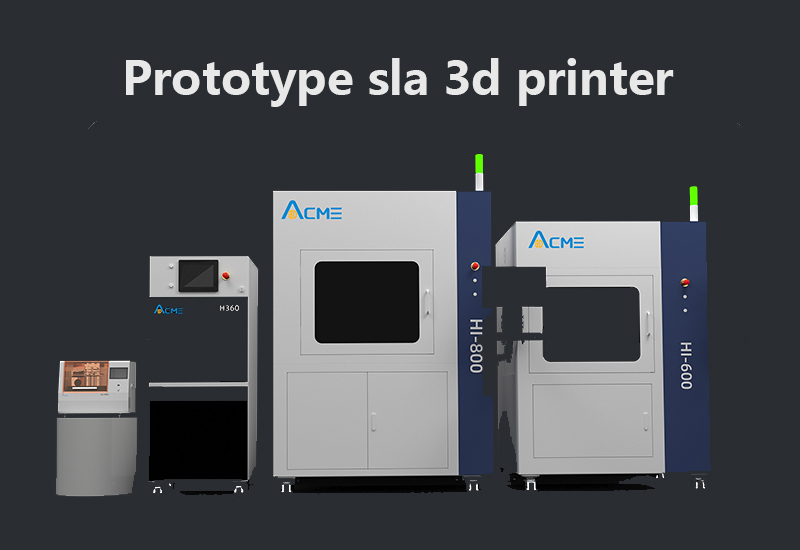

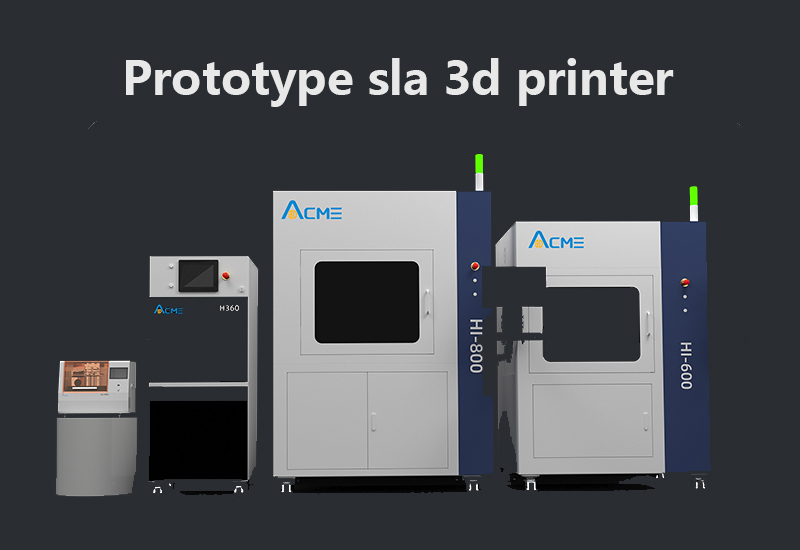

As a powerful brand in the field of industrial 3D printers, ACME continues to introduce high-performance, high-quality, and high-efficiency 3D printing equipment to provide better printing solutions for various industries.

ACME is a leading 3D printing solution provider in China, and its

industrial-grade 3D printers are well recognized in the industry. Among them, ACME SLA series 3D printers are specially designed for industrial applications, featuring high precision, high efficiency, and high reliability, and can meet the application requirements of aerospace, automotive, and medical fields.