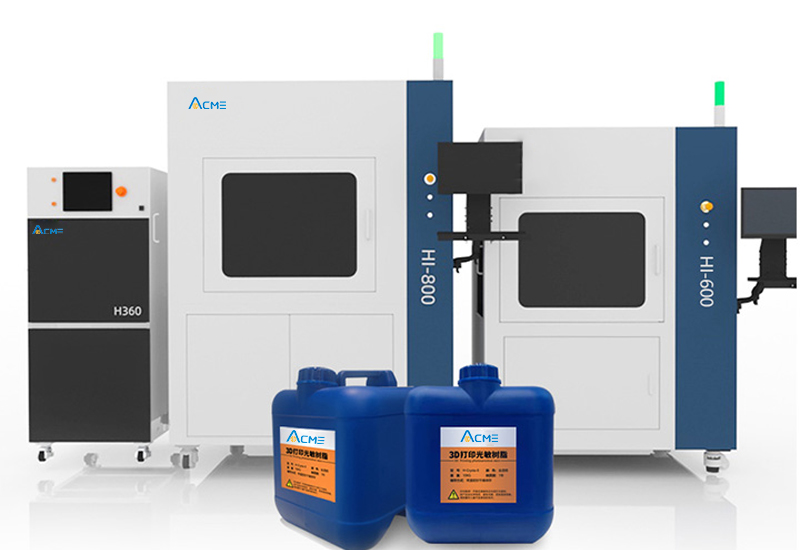

sla refers to a method of 3D printing molding, which has been accepted by the public and widely used due to its diversified materials and low price. sla stereoscopic photocuring molding technology has the advantages of high accuracy and good quality, so it enjoys a high reputation in the field of 3D printing, and is also known as "the most mature 3D printing technology". In the following, Acme 3D printer manufacturers explain the sla stereoscopic optical curing forming technology through slad structure, working principle, sla printer application scope, sla printer advantages and other aspects.

What is an SLA?

SLA is an additive manufacturing process modeled by selectively curing a polymeric resin layer by layer using an ultraviolet (UV) laser beam. The material used in SLA is a liquid photosensitive thermosetting polymer. As the first 3D printing technology, SLA made a name for itself early on, with its inventors filing a patent for the technology back in 1986. SLA is an extremely cost-effective 3D printing technology for models that require high precision or smooth surfaces.

Working principle of SLA

The liquid tank is filled with liquid photosensitive resin, and the ultraviolet laser beam sent by the ultraviolet laser laser is scanned point by point on the surface of the photosensitive resin according to the section information of each layer of the parts under the control of the control system, so that the thin layer of the resin in the scanned area generates photopolymerization reaction and solidifies, forming a thin layer of the parts.

After a layer of curing, the workbench moved down a thickness of the distance, so that in the original cured good resin surface and then coated with a new layer of liquid resin, scraper will viscosity of the resin liquid level scraping, and then the next layer of scanning processing, the newly cured layer firmly bonded to the previous layer, so repeated until the whole part is manufactured, get a three-dimensional entity prototype.

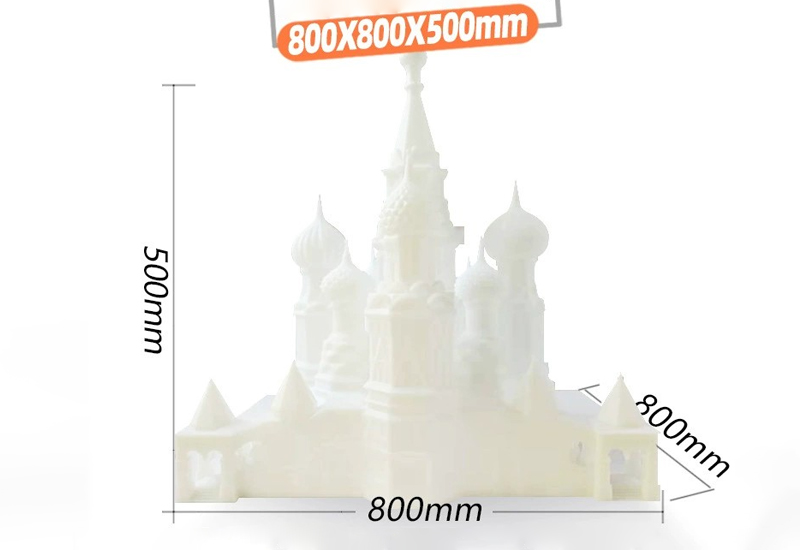

Application scope of SLA printer

Due to these advantages of SLA 3D printing technology, it can be used for rapid processing of high-precision, high surface quality, multi-detail hand plate samples, automotive molds, medical biology, Conceptual models, general components, appearance verification, assembly verification in military industry, footwear industry, cultural innovation, education and scientific research, aerospace, consumer electronics, game animation, architectural design, sculpture modeling, home decoration and other fields can be used for functional testing in some cases. In addition, can also be used for those special requirements have the corresponding characteristics of materials, such as heat resistance, full transparency, etc.

Advantages of SLA printers

1. Photocuring is the earliest rapid prototyping process with high maturity and time testing.

2, the CAD digital model directly into prototype, processing speed, short production cycle, no cutting tools and molds.

3, can process the structure and shape of complex or the use of traditional means is difficult to form the prototype and mold.

4. Make CAD digital model intuitive and reduce the cost of error repair.

5. Provide samples for the experiment, which can verify and check the results of computer simulation calculation.

6, online operation, remote control, conducive to the automation of production.

Nine factors that affect the print speed of SLA

1. Workpiece orientation and shape: the workpiece orientation has a great impact on the printing speed when printing, but it is often ignored. Just turning the workpiece orientation to a different Angle, or reversing 180° can greatly shorten the time required for a complex molding, which is related to the movement of the scraper. When a layer is cured, the scraper needs to sweep over the newly cured part to ensure that the resin material is evenly covered and the pool is completely level. This process is slow, much slower than curing a single layer. The reason the scraper moves slowly is to reduce the disturbance to the resin material. After the scraper completes this process, it needs to wait a short period of time for the small fluctuations in the resin material to disappear.

If you can reduce the time required for this step, you can save a lot of time overall, and this is where the artifacts come into play. For work pieces where most of the material is distributed on the same side, it is important to position this side closest to the starting position of the scraper to reduce the distance the scraper can travel each time.

2. Spatula spreading speed: As mentioned above, the slow movement of spatula greatly prolongs the entire printing process. In addition to placing the workpiece wisely and minimizing the distance of the scraper, the speed of the scraper movement can be adjusted, but care should be taken when increasing the speed of the scraper. The faster the scraper moves, the higher the likelihood of fluctuations on the resin surface, which will not only affect the print quality of the workpiece, but in some cases may indeed reduce the print speed. If the device is fitted with a resin sensor, fluctuations in the surface of the resin can be detected and the device waits for the fluctuations to subside before conducting the next scan, negating the advantage of faster scraper movement.

3. Layer thickness: The influence of layer thickness on the printing speed is direct. The smaller the thickness of a molding layer, the more layers need to be printed, and the printing time is correspondingly extended. Of course, because of the improved Z-axis resolution, one would expect more layers to be printed. One of the factors that we often overlook is that if you print with a relatively high layer thickness, although you can save a lot of time at the printing stage, the effect of the bulge on the workpiece will also be aggravated. The bulge usually needs to be dealt with at the post-processing stage, so the time saved by printing fewer layers at the time of printing is taken up by additional grinding and polishing.

4. Scanning speed: You might think that scanning speed (the speed of the laser when curing the resin layer) would be one of the main factors affecting printing speed, but in reality it has very little effect. Scanning layer by layer takes much less time than other parts of the printing process, such as coating, so increasing the scanning speed of each layer can only save a fraction of the time. Of course, if the molding time is long, then the time savings can add up, especially in the case of a large amount of resin per layer, but we can not increase the scanning speed to speed up the workpiece printing. Because if the laser scanning speed is too fast, the curing time of the resin is insufficient, so the scanning speed is usually limited by other factors.

5. Scan spacing: Scan spacing is one of the key parameters in SLA printing. Sweep spacing refers to the distance between each spot scanned by the laser. The closer the spots of the beam are, the more spots are needed and the longer it takes to print. Although the wider scanning spacing can shorten the printing time, but similar to the thick layer, will cause rough edges, increase the post-processing workload, this must be kept in mind. In some cases, although the printing time is shortened, but the overall delivery time has been extended, for the precision of the workpiece is not high, widening the scanning spacing is a good way to speed up the forming.

6. Material: The nature of the resin material used for printing has a great impact on the printing speed. The curing speed of resins curing into flexible materials is different from that of resins curing into hard and strong materials. The different curing speed affects the printing speed. Resin materials curing longer are not suitable for printing at high scanning speed. As a result, some resin materials can only be printed slower, while others can be printed faster without adverse effects.

7. Sensor: Each SLA printer has a sensor to monitor the liquid level and surface fluctuation of the resin in the material pool. Fluctuations are caused by the movement of the coated blade, and sometimes the environment causes the surface to fluctuate. To maximize accuracy, the sensor can be set to be highly sensitive and delay the next scan until all fluctuations in the pool are completely eliminated.

Of course, this conservative approach means spending a lot of time waiting for the resin to become completely stationary. If you want faster printing, you can set the sensor more loosely, allowing for the tiniest fluctuations that speed up the printing process. When adjusting the sensor, it is important to consider the resin material used, the speed of the coating scraper and the surrounding environment. Printing a work piece in a building that shakes frequently may greatly slow down the molding speed.

8, vibrator quality: vibrator is one of the key components in SLA printing, is the core part of laser control. You might think this would have a big impact on print speed, but in fact print speed is limited by some of the other factors mentioned above. High scanning speeds may be possible with high quality galvanometers, but such high scanning speeds are often not available due to the limitations of the resin material and the actual curing process. Although the quality of the galvanometer cannot be said to have no effect on speed, it has a greater effect on accuracy and durability than on speed. After all, the high accuracy allows us to be more flexible in our Settings to maximize both speed and precision.

9. Use of molding space: One of the advantages of industrial grade SLA printers over desktop grade SLA printers is that industrial grade SLA printers can print multiple jobs in a single molding space, relying on a face-up printing direction and a wider and deeper resin pool. Maximizing the use of all the space in the pool is one of the ways to speed up batch job printing. Using a molding room to print 16 jobs at the same time is much better than running the equipment twice, printing 8 jobs each time.

Sometimes a degree of rearrangement is required, but it usually saves time in the long run to better fit the workpiece into the molding room space. While there is no saving time in the molding scanning phase (the same amount of material needs to be cured), reducing the number of molding times can greatly reduce the number of scraper spreads and the total number of layers in the batch. Since scraper spreading and Z-axis movement are the slowest parts of the printing process, reducing these times can significantly save overall printing time.

+86 19958086067

sales@3dacme.com