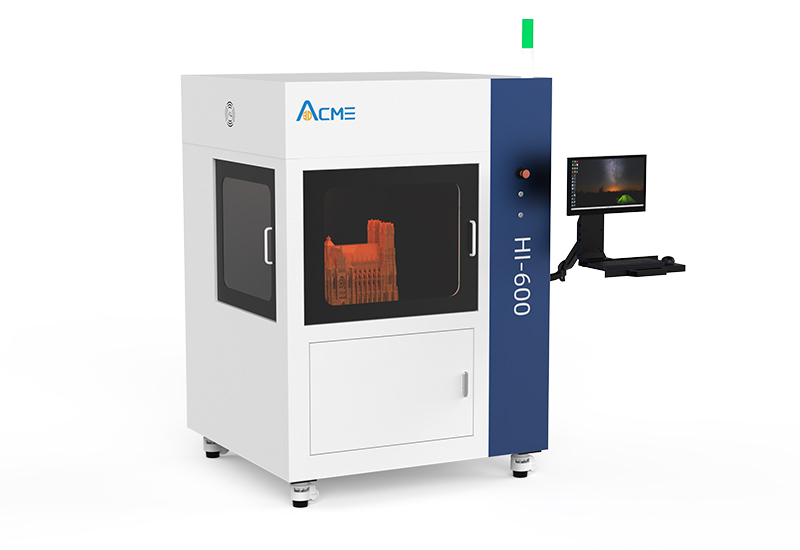

Photocurable 3D printing technology is a relatively mature technology in the 3D printing industry. The application field of photocurable 3D printer is also very close to our life, such as: hand processing, art products, mold models, dental molds, etc., you can see the products produced by the photocurable 3D printer. Like our common light curing 3D printer according to the working principle can be divided into three types, namely SLA light curing 3D printer, DLP light curing 3D printer and LCD light curing 3D printer. Today Acme3d is going to talk about how it works and how it compares, so that you can choose the right photocured 3D printer.

Principle of light curing 3D printer

First, SLA light curing 3D printer SLA forming principle is mainly the use of ultraviolet light as a light source, and then through the vibration mirror system to control it, so that it first draws the shape of the object on the surface of the liquid resin, and then the object falls down for a distance, and then the platform is immersed in the liquid resin, so repeated, constitute the solid printing.

Second, the basic principle of DLP light curing 3D printer DLP molding, the model is first cut into layers with 3D printing software, and then the shape of the first layer of resin model is projected, and then light curing molding, the first layer of molding, will slightly increase the object, to the resin projected the shape of the next layer of model, so repeat, layered printing model.

Three, LCD light curing 3D printer in the actual principle of LCD and DLP principle is basically similar, the difference is that the light source of DLP is replaced by LCD. The imaging principle of LCD liquid crystal plate is adopted. The red, green and blue primary colors of the filter are used to filter out the infrared and ultraviolet light which have a certain destructive effect on the LCD board (have a certain damage to the LCD board), and the three LCD boards are projected into three primary colors.

How to choose a light curing 3D printer?

Comparison of SLA, DLP and DLP three molding technologies

Molding speed: DLP> LCD> SLA

Printing accuracy: DLP> SLA> LCD> FDM

Print size range: SLA> DLP> LCD

Material range: (DLP≈LCD)> SLA

Service life of main components: DLP≈SLA> LCD

Machine price: SLA> DLP> LCD

Consumable price: SLA≈DLP≈LCD

Through the molding technology, printing accuracy, component service life, 3D printer price, consumable price convenient comparison of three kinds of photocuring 3D printer can let you know more clearly about the performance of all aspects of the equipment, convenient for you to choose to buy the appropriate photocuring 3D printer.

+86 19958086067

sales@3dacme.com