As a 3D printer manufacturer, Acme aims to better help enterprises reduce R&D or manufacturing costs. For example, photocuring resins frequently used in SLA printers are 3D printing consumables frequently used. The average price of standard SLA resin 3D printing materials is about $30 per kg. Prices will be higher. The better the resin, the smoother the finish, the higher the quality and the finer the detail. We often say that you get what you pay for, and resin materials are no exception. At the same time, the use of high quality resin materials, our post-processing work will become easier. So saving resin material equals saving time and money. In actual 3D printing, there are many ways to control resin consumption. Below we will briefly list five ways to save light curing resin for your reference.

3D printing material consumption is related to volume: the smaller the volume, the less consumption. So sometimes, cut-out models are necessary. In hollowed out models, there are two things to pay attention to: wall thickness and drain holes. Minimizing wall thickness does seem like a way to save money. However, as the wall thickness becomes thinner, the model becomes weaker, and it is easy to crack parts of the model. In addition, when printing the hollow model, the resin may be blocked in the model and cannot be discharged due to the layer curing. At this point, it is necessary to add drain holes to drain the resin in the hollow model. The 3D model can also be hollowed out using slicing software. For example, CHITUBOX only needs a few clicks to hollow out the model and add drainage holes.

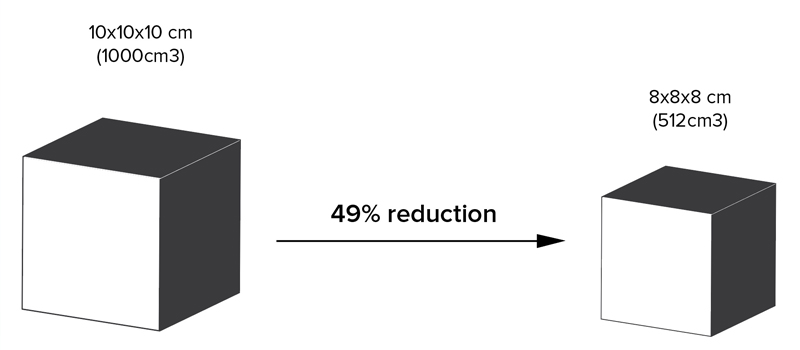

The material consumption of 3D printing also depends on the size of the model: the smaller the size, the less it consumes. Use slice software to adjust the scale and adjust the size of the model. Such as adjusting the scale X, Y, Z direction size, can also adjust the consumption of light curing resin.

Reduced scale diagram

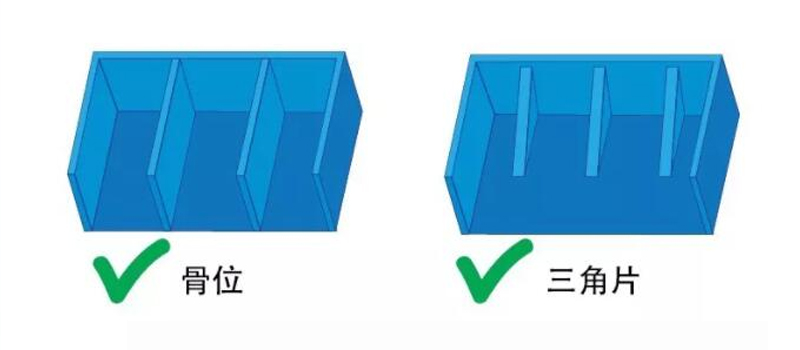

You know, the biggest waste of light curing resin is actually print failure. Therefore, it is of great significance to optimize the structure of 3D model and improve the success rate of printing. For example, the thinner the outer wall, the lighter the model will be, the less photocured resin it will need to print, and the cheaper it will be but the more fragile it will be. This is especially important when using a pull-up 3D printer, where the model is suspended upside down and the gravitational pull (large model) and pull are greater. Acute angles will increase stress concentration, which is easy to make the model crack or print failure. Small holes (less than 0.5mm in diameter) are also tricky to print because they can close up during printing. To reduce the potential risk of breakage and pressure changes after 3D printing is completed, bone placement (reinforcement) or triangle pieces can be added to the model.

Bone position and trigonometric model

The consumption of 3D printed materials can also be improved by avoiding or reducing the use of braces and bottom rafts. Do not want to waste light curing resin material, should effectively add support and bottom raft. In some cases, unnecessary resin waste can be reduced simply by adjusting the placement of the model in the slicing software. Reducing unnecessary support structures not only reduces the resin material cost and total printing time (SLA printing) of 3D printing, but also results in a higher surface quality of finished products. This is because if there are more support structures, the contact points and area between the model and the support will be more, which is easy to cause surface damage when removing the support structure, resulting in the formation of potholes, rough and dull surface.

By printing as a whole, 3D printing can skip some assembly processes to reduce material consumption, while also saving on the labor cost of assembly. Opel, for example, has shown that by optimising the assembly process it can cut costs by 90%. Another example is Jabil's Auburn Hills plant, which also uses additive manufacturing and now costs 30% less to process. Although this is related to the industry and the 3D printing technology used, there is no denying that overall printing can help reduce material consumption.

All of the above five methods help save light curing resin materials. Of course, there are many ways to save light curing resin, 3D printing (additive manufacturing) as a new industrial technology, cost control can be considered from many aspects, welcome to discuss and study with Harbin 3D, if you do not understand can also call us to consult.

+86 19958086067

sales@3dacme.com