With the deepening of domestic 3D printing market application degree, 3D printing technology has appeared in a variety of different fields. Like aerospace, automotive, shipbuilding, nuclear industry, mold and other industries. More and more enterprises choose 3d printers for production and research and development. 3D printing technology is an emerging technology in the processing and manufacturing industry, and it is also a powerful supplement to manufacturing means. Meanwhile, 3D printing has begun or already replaced traditional manufacturing means in some manufacturing fields. 3D printing technology is a complement to traditional machining manufacturing, so under what circumstances should companies consider using 3D printers to replace CNC manufacturing? Under what circumstances do companies choose to use 3d printers for production and development? Harbin three-dimensional Xiaobian summed up some experience hope to help you.

1. Enterprises can consider 3D printers because of the complexity of traditional processes

After thousands of years of development, it can be said that the traditional manufacturing industry can meet the vast majority of manufacturing needs, but some technical problems are still difficult to overcome, such as complex structure, large-scale customized products. There are two very representative cases: GE additive 3D printing engine fuel nozzle, 3D printing invisible braces.

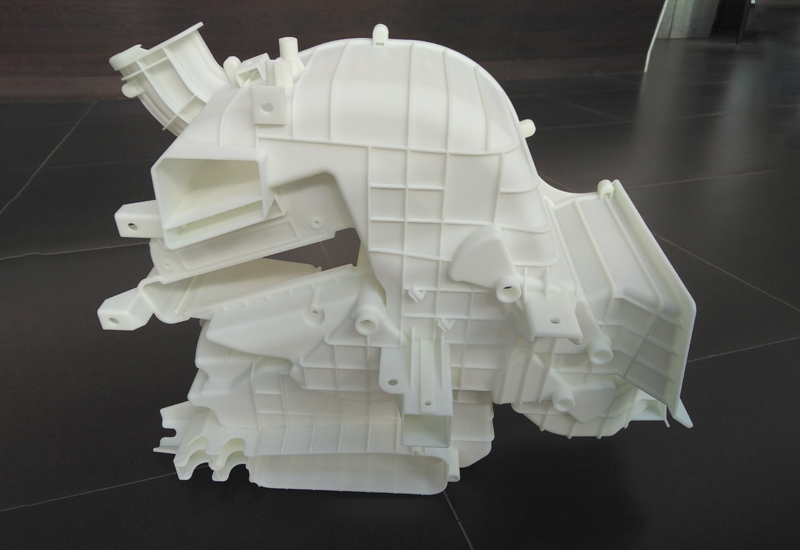

GE Additive 3D Printed engine Fuel Nozzles: The fuel nozzles used in the LEAP engine were originally assembled from 20 parts, all of which were manufactured by conventional machining methods. GE Additive has redesigned it, combining 20 parts directly into one unit. At this time, it is impossible to make it by using traditional machining methods, but 3D printing can be perfectly made. The benefits include a 25% reduction in fuel nozzle weight, a fivefold increase in life, and a 30% reduction in manufacturing costs. Today, GE Additive produces about 40,000 fuel nozzles a year, all printed on metal 3D printers.

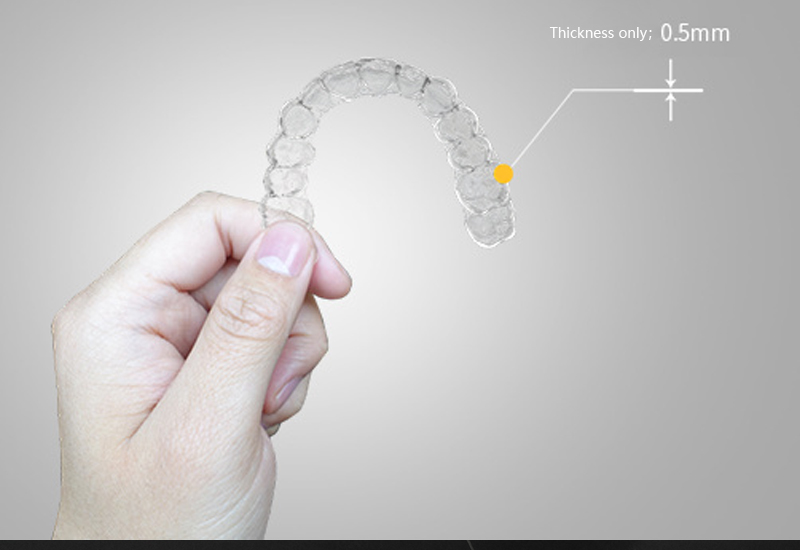

3D-printed invisible braces: Each pair of invisible braces contains dozens of braces, each with a slightly different shape. Each of the braces is coated on a different mold, which requires the use of a light-curing 3D printer. Because the traditional way to make dental mold is obviously not practical. As invisible braces have their own advantages, they have been accepted by some young people. Many invisible braces manufacturers at home and abroad have started large-scale production, and the market space is very huge.

2. Enterprises with high manufacturing costs and low efficiency can consider 3D printers

Enterprise profit is often in the cost and efficiency control, such as small demand for product manufacturing, traditional manufacturing mold production cost is high, do not open mold production efficiency is low. Even if the order is sent to the manufacturing plant, the factory's schedule is much later. At this time, 3D printing again reflects its own advantages, no need to open the mold can manufacture complex technology, a whole molding even assembly manual are saved. Saving time and labor greatly improves the production efficiency, and the production period can be controlled by oneself. Maybe some people will say that I don't necessarily need to buy a 3D printer from my own company. I can find a 3D printing service provider to do it for me, but the cost will rise and the work schedule will be out of my control. Of course, the amount of less or no requirements for the duration of this operation is also a good choice.

3. The product is updated and iterated quickly, and enterprises that need to speed up production and research and development can consider 3D printers.

In order to meet the market demand, many enterprises need to accelerate the speed of production and research and development due to the rapid product update and iteration. In traditional manufacturing, it often takes a long time to develop a product from design to production. However, 3D printing technology can be used to solve the problem in less than one week from design modeling to manufacturing and production, greatly shortening the research and development cycle. For example, many enterprises also hand over the design of products to 3D printing service providers to save the research and development cycle. Many 3D printing service providers in the market can provide guarantee such as starting from 1 piece and delivery in 24 hours, which greatly improves the efficiency. Many companies say that "using 3D printing is addictive", and R&D companies often want to set up their own 3D printing studios.

4. In order to meet the demand of customized market, enterprises can consider 3D printers

Personalized customization has always been a direction of market demand. For consumers, customization can meet diversified and personalized needs and enhance the sense of experience. The brand can establish a high-end, professional, young image for itself, and further enter the youth market; At the same time, customization can promote industrial innovation and upgrading. Based on the advantages of low cost customization of 3D printing, the aviation industry, biomedicine and personal consumption are the most potential applications. During the 13th Five-Year Plan period, 3D printing will be the first to be widely used in the aviation industry in China. In January 2013, the "Laser Forming Technology of Large complex integral component of Aircraft titanium Alloy" won the first prize of the National Technological Invention Award. China has become the second country in the world that has mastered laser rapid forming and technology of aircraft titanium alloy structural components, and the only country in the world that has mastered the manufacturing and application of large main bearing component of laser forming titanium alloy. Industrial sectors such as the aviation sector and automotive manufacturing are among the areas where this type of 3D printing technology can take advantage, and its application will enter a period of rapid growth in the coming years.

The application of 3D printing in the field of biomedicine has preliminarily emerged. Currently, the main applications being explored are dentures and prosthetics. When 3D printing technology is combined with medical image modeling and simulation technology, it can also be widely used in the manufacturing of artificial prostheses, implants, artificial tissues and organs. With the further breakthrough of printing equipment and printing materials technology and the further reduction of cost, 3D printing in the field of personal consumption (food, artwork, personalized items, etc.) will also be further developed. During the 13th Five-Year Plan period, 3D printing will have a profound impact on the production mode of manufacturing enterprises, leading the manufacturing industry from standardization and lean production to customized production. After the "13th Five-Year Plan" of solid development, to the "14th Five-Year Plan", with the help of network and information technology, our country is expected to initially form the new manufacturing industry model represented by "individual creativity + community building + cloud manufacturing".

5. In order to reduce material waste and environmental pollution, enterprises can consider 3D printers

Affected by environmental problems, the country has promoted the transformation and upgrading of low-end and polluting manufacturing industries, and many factories have been forced to move out or shut down. At this time, it is necessary to consider the use of 3D printing and other more advanced technologies to replace part of the process, reduce material waste and reduce environmental pollution. For example, 3D printing of metal crown, 3D printing of casting sand mold, 3D printing of wax mold of jewelry, etc., are replaced by 3D printing technology in some aspects of the original manufacturing process.

The above is collected by Acme Xiaobian for you. Under what circumstances, enterprises choose to use 3d printers for production, research and development management. I hope it will be helpful to you. If enterprises encounter the above situations, they need to consider the use of 3D printing to help their own enterprises upgrade, make products that others can not do, save costs and improve efficiency, and ensure that their own enterprises have advantages in the competition. Acme3d focuses on the research and development, manufacturing and industry application solutions of 3D printing equipment. Welcome to discuss the application solutions of 3D printing industry together.

+86 19958086067

sales@3dacme.com