Sand table model is widely used in military, exhibition hall, construction industry, real estate and other industries. The traditional sand table model production is relatively complicated and the cycle is relatively long, which can no longer meet the market demand for complex structure sand table model. At present, the sand table model production is not simply using the traditional production methods, but also some new production methods, such as the popular SLA light curing 3D printer to make the building sand table model is one of the ways.

Sand table model application

Sand table model is not only widely used in the military, in some exhibition halls, construction industry, sales office and other places have been widely used, like the sales office of the real estate model is a form of sand table model, mainly used to show customers, overlooking the overall situation, can understand the layout of the community through the model, planning and so on.

3D printing of building models for real estate

Traditional sand table making method

The traditional way of making sand table model, mainly taking the construction industry as an example here, the traditional sand table making needs to make a graphic design sketch first, the production company designs the structure of the building in proportion to the sketch, then breaks it down into different plates, adds the architectural details in accordance with the design requirements, and then sends it to the engraving machine to carve out all the plates on the PVC plate, and finally assemble and glue. The whole production cycle usually takes two to three months, of course, depending on the size and complexity of the sand table model.

3D printing sand table production method

Compared with traditional sand table manufacturing, 3D printing not only simplifies the sand table production process, shortens the production cycle, but also significantly reduces the production cost. Now 3D printing is based on digital manufacturing process, combining accurate virtual 3D models with real physical objects. Sand table production only needs two steps: 3D digital model design and 3D printer printing of finished products. The raw materials are mostly nylon plastic and photosensitive resin, and the price is cheap. In complex or special-shaped sand table production advantage is more significant.

3D printing model of retro architecture

Use SLA

Light curing 3D printer

advantage

First, time

SLA light curing 3D printing technology improves work efficiency, SLA light curing 3D printer integrated molding, reduce a lot of redundant steps, SLA light curing 3D printing enables designers to quickly make the prototype of the item in their mind, and ultimately save time in the design process. This allows new or improved products to get to market faster than traditional methods.

Second, space

Industrial grade 3D printer

The floor area is not big at all. Dozens of 3D printing machines can be placed in a small factory building, which saves a lot of space.

Third, the environment

The traditional process of making large sculpture crafts generally uses gypsum and glass steel to turn molds, during which a lot of dust pollution and waste materials will be produced. The products produced by SLA light curing 3D printer are free of dust, waste, pollution and environmental protection risks.

Fourth, the cost

SLA light cure 3D printing technology reduces significant costs. The SLA3D printer is intelligibly manufactured without human care, reducing labor costs. Since SLA light cure 3D printing utilizes the concept of adding materials rather than subtracting materials, there is little waste in the process. While the materials used in traditional manufacturing methods are recyclable, the process costs money, and the SLA3D printer offers significant savings.

5. Complexity

SLA light curing 3D printing technology is not affected by complexity, and can accurately print complex parts. Many hollow and hollow structures that cannot be made by traditional processes can be completed by 3D printing, and different product requirements can be customized. Complex sand table building models can be directly integrated printing models without complicated process links.

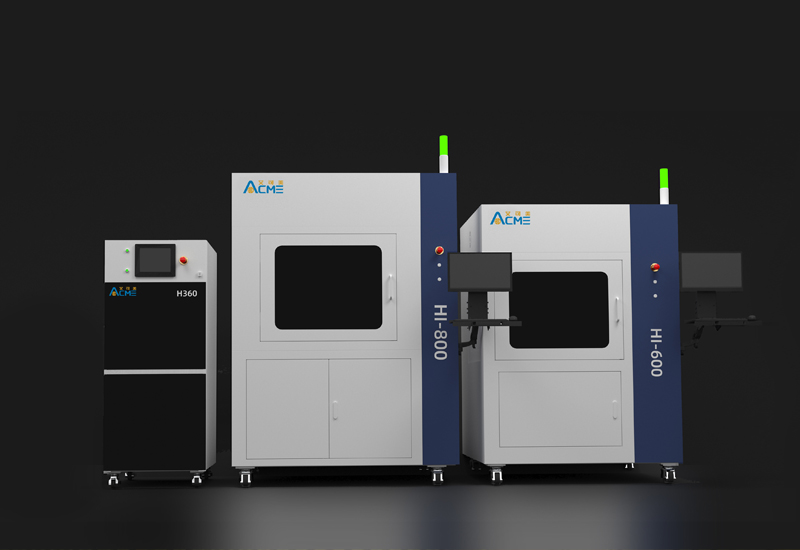

SLA light curing 3D Printer HI600

Sand table building model 3D printer recommended

The accuracy of H360 industrial 3D printer is 0.05~0.1mm, the printing size is 360X360X300mm, the SLA light curing technology is adopted, and the principle is photosensitive resin material. The printed model surface is smooth and delicate, and it is easy to grind and color. For the 3D printing sand table building model can meet the size, details, cost and speed of many aspects of the demand.

+86 19958086067

sales@3dacme.com