As a very mature rapid prototyping technology, SLA light-curing 3D printing has a very wide range of applications in various industries. Many customers who inquire about SLA photo-curing 3D printers also want to know its working principle and what is the process of SLA photo-curing 3D printer model processing? We have already talked about the working principle in the previous issue. For details, please refer to: Detailed explanation of 3D printing technology - sla stereolithography technology. Here is mainly to explain the SLA light curing 3D printer model processing process, I hope it will be helpful to everyone.

SLA light curing 3D printer product model

SLA light curing 3D printer model processing process

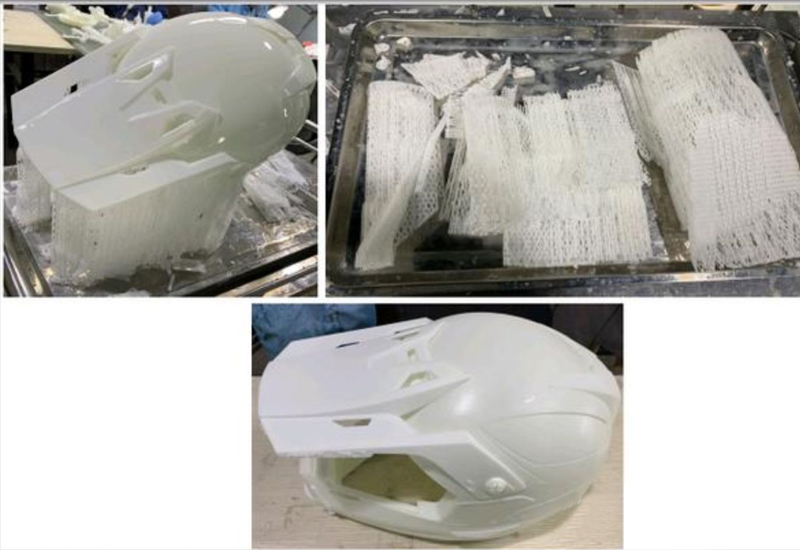

1. Model taking and cleaning: Take out the model + support as a whole from the SLA printer platform with a spatula, and put it into a tray container. Because most of the printed models of SLA light-curing 3D printers are completely immersed in the liquid resin raw materials, when the printed model is taken out of the printer, the model is completely covered by uncured resin. It must be rinsed off before proceeding with the next steps. The cleaning process can use an ultrasonic cleaning machine, which is a simple and efficient method. Add isopropanol to the ultrasonic cleaning machine to completely cover the model, turn on the ultrasonic cleaning function, and the resin on the surface of the model can be completely removed in a few minutes. Take out the model and dry it to get a smooth and clean model.

3D model without dismantled support and dismantled support renderings

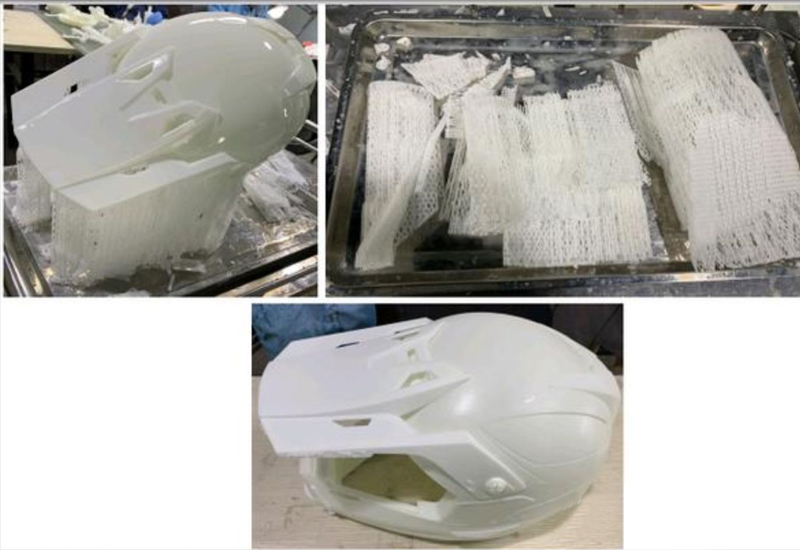

3D model without dismantled support and dismantled support renderings 2. Support removal: In the process of model printing, there are some hollow positions that need to print support structures, and the next step is to remove these support structures. In this process, if we don't care much about the smoothness and integrity of the model's surface, directly destroying the supporting structure by hand is the fastest and most convenient way. However, if we need good surface integrity, it is best to carefully remove the support structure with sharp diagonal pliers or cutters. Both removal methods will leave small bumps on the print. This requires grinding after curing.

The support of the model is removed, and no surface effect drawing is made

The support of the model is removed, and no surface effect drawing is made3. Curing treatment: The model without the support structure has not yet reached the hardest state of the model, so it needs to be put into the curing box, cured for about 10-15 minutes, and then the model is turned over and cured for another 10 minutes. When sanding, the sandpaper needs to be polished with water, so that the polished model has a higher finish and faster efficiency.

the

3D model after grinding spray painting effect

3D model after grinding spray painting effect4. Grinding treatment: The hardness of the cured model has been greatly improved, and at the position where the support is removed, the remaining bumps need to be polished to obtain a complete SLA light-cured 3D printing model.

5. Model process: In order to meet the market demand, the model printed by SLA light-curing 3D printer can also be painted, electroplated, colored, and the polished model can be processed in various depths according to different needs. Note: Before doing the surface treatment process, the printed model should be finely polished and polished. The polished model should not appear to have any layers, and the whole will be more perfect.

Effect picture of 3D model after polishing and electroplating treatment

Effect picture of 3D model after polishing and electroplating treatmentAcme 3D focuses on the R&D, manufacturing and industrial application solutions of 3D printing equipment; focuses on the construction of modern, intelligent and digital industrial manufacturing scenes for 3D printing; focuses on the R&D and process development of technical equipment in 3D printing related fields. From the research and development, production and sales of 3D printing equipment, printing consumables and customized products, it has realized the vertical layout of the whole industrial chain.