What should companies pay attention to when purchasing industrial-grade 3D printers?

Because the traditional industrial manufacturing process consumes a lot of time and cost in the production of complex structural models or products, and many design concepts are difficult to realize with traditional production methods, so many companies consider using 3D printers to realize product development or manufacturing. , so what should companies pay attention to when purchasing industrial-grade 3D printers? What 3d printer brand do you recommend? The editor of Harbin Engineering 3D has sorted out some information, hoping to be helpful to everyone.

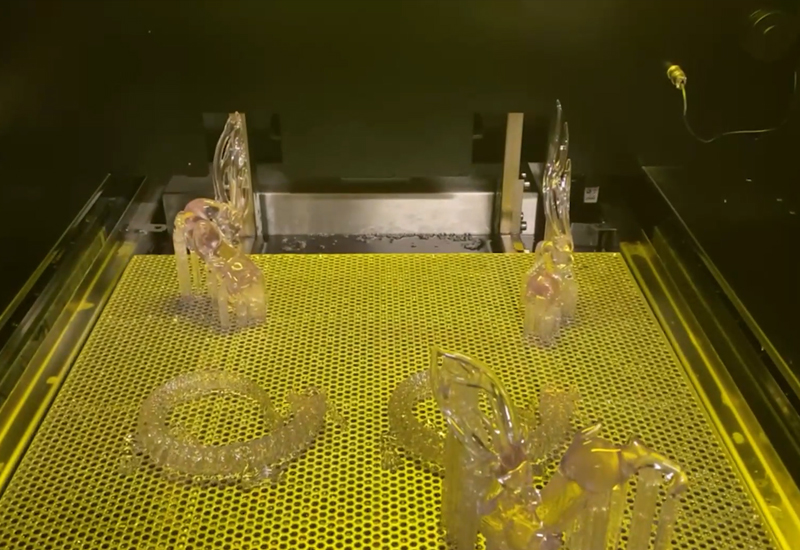

SLA light curing industrial 3D printer

What should companies pay attention to when purchasing industrial-grade 3D printers?

(1) What technical types of industrial-grade 3D printers can meet the needs of your company:When purchasing industrial-grade 3D grades, enterprises need to clarify product requirements, whether they are used for product development or direct production, the products need to be used, and what types of materials are used in the products. Commonly used industrial 3D printers include FDM, SLM, Polyjet, MJP, GLA, DLP, EBM and other technical types. For industrial 3D printers of different technology types, the printing materials are not used. For example, SLM is used to print metal materials, SAL is used to print resin materials, and FDM is used to print nylon and plastic materials. Some technical types and the materials that can be printed are listed in the table below:

| Types of |

accumulated technology |

basic material |

| extrusion |

Fused Deposition (FDM) |

Thermoplastics, eutectic system metals, edible materials |

| Wire |

Electron Beam Free Forming (EBF) |

Almost any alloy granular |

| 粒状 |

Direct Metal Laser Sintering (DMLS) |

Almost any alloy granular |

| Electron Beam Melting Molding (EBM) |

Titanium alloy |

| Selective Laser Melting (SLM) |

Titanium alloy, cobalt chrome alloy, stainless steel, aluminum |

| Selective Heat Sintering (SHS) |

thermoplastic powder |

| Selective Laser Sintering (SLS) |

Thermoplastics, metal powders, ceramic powders |

| Layer nozzle 3D printing |

Gypsum 3D printing (PP) |

plaster |

| laminated |

Layered Object Manufacturing (LOM) |

Paper, metal film, plastic film |

| Photopolymerization |

Stereolithography (SLA) |

light hardening resin |

| Digital Light Processing (DLP) |

light hardening resin |

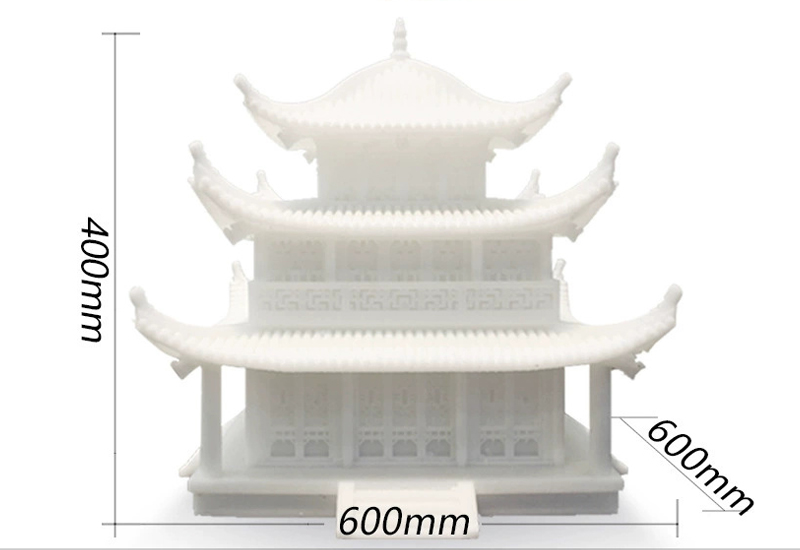

Traditional turning, milling, planing and grinding processes and 3D printer processes are all designed to meet the needs of enterprises. Some enterprises purchase 3D printers to meet product development needs and print models to meet assembly structure verification. Some people want to manufacture finished parts to meet the requirements of use. Requirements determine the size, specification, material type and forming accuracy of the purchased equipment. The price of industrial-grade 3D printers ranges from hundreds of thousands to tens of millions, and the price of 3D printing equipment is directly proportional to the size of the molding and the amount of materials.

(2) Enterprises purchasing industrial-grade 3D printers need to pay attention to the use of environmental factors:3D printing equipment requires different environments for different technologies. Consumer machines have very simple requirements for the place of use, usually a well-ventilated place indoors. SLA and DLP use open storage resins, which have certain requirements on the environment like temperature, humidity, the best temperature control for SLA and DLP technology type 3D printers is 22-26, humidity is 40%, indoor ultraviolet rays are low, avoid natural light, Requires special printing space.

For industrial-grade metal 3D printers, whether it is powder feeding in the cabinet, electron beam or coaxial powder feeding, the environmental requirements are much more relaxed. When installing industrial-grade 3D printing equipment, the size of the equipment and auxiliary equipment should also be considered. Of course, before purchasing the equipment, the 3D printer manufacturer will also clearly inform the 3D printing equipment and supporting equipment, which environment and what kind of venue is needed, and the enterprise must plan the venue in advance before purchasing the 3D printer.

(3) Enterprises purchasing industrial-grade 3D printers need to pay attention to operator training for equipment supply:3D printing preparation: 3D data processing, supporting design and layout, with emphasis on software operation. Much of the slicing software currently used by 3D printing manufacturers is custom materialized modules, some of which are self-developed or acquired. Therefore, to consider whether our engineers are familiar with 3D modeling, whether the 3D printer manufacturer has training.

(4) Enterprises purchasing industrial-grade 3D printers need to pay attention to the selection of consumables:The rapid development of new materials is an important driving force for the rapid growth of the 3D printing industry. 3D printing is suitable for material states of solid, liquid and gas, and the material types include metals, resins, polymers, ceramics, inorganic lipids, biomaterials, etc. 3D printing can use a variety of materials, but in reality, there are often no materials that fully meet the requirements. In a certain category, existing 3D printing technologies can only print a limited number of materials. Manufacturers of industrial 3D printing equipment are recommended to provide a detailed material parameter table when selecting materials to find out whether there are alternative or similar materials that can meet the final requirements.

(5) Enterprises need to pay attention to the purchase of industrial-grade 3D printers. 5. Enterprises should pay attention to the after-sales service of equipment providers when purchasing industrial-grade 3D printers:

It is very important to have an after-sales team with abundant spare parts and mature technology. At present, many industrial-grade 3D printer manufacturers have it. 3D printing equipment is highly automated. As long as we strictly follow the manufacturer's process, the failure rate is usually very low. Of course, some equipment on the market is inferior, so professional purchasing consultants can do more with less. After all, every industrial-grade 3D printer is expensive.

The above is how to choose an industrial-grade 3D printer. What should companies pay attention to when purchasing industrial-grade 3D printers? I hope it will be helpful to everyone. If you want to know more information and knowledge about 3D printing, you can also contact Acme3D if you are looking for an industrial-grade 3D printer manufacturer. Consider the choice of consumables:

The rapid development of new materials is an important driving force for the rapid growth of the 3D printing industry. 3D printing is suitable for material states of solid, liquid and gas, and the material types include metals, resins, polymers, ceramics, inorganic lipids, biomaterials, etc. 3D printing can use a variety of materials, but in reality, there are often no materials that fully meet the requirements. In a certain category, existing 3D printing technologies can only print a limited number of materials. Manufacturers of industrial 3D printing equipment are recommended to provide a detailed material parameter table when selecting materials to find out whether there are alternative or similar materials that can meet the final requirements.

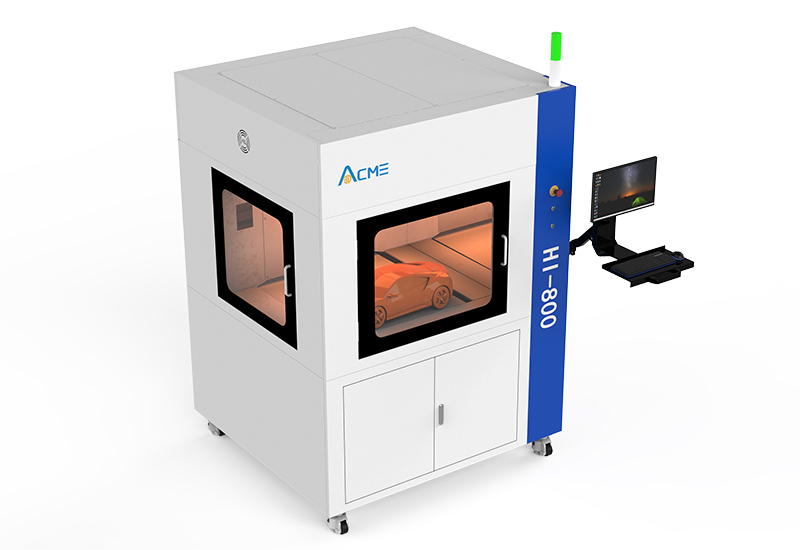

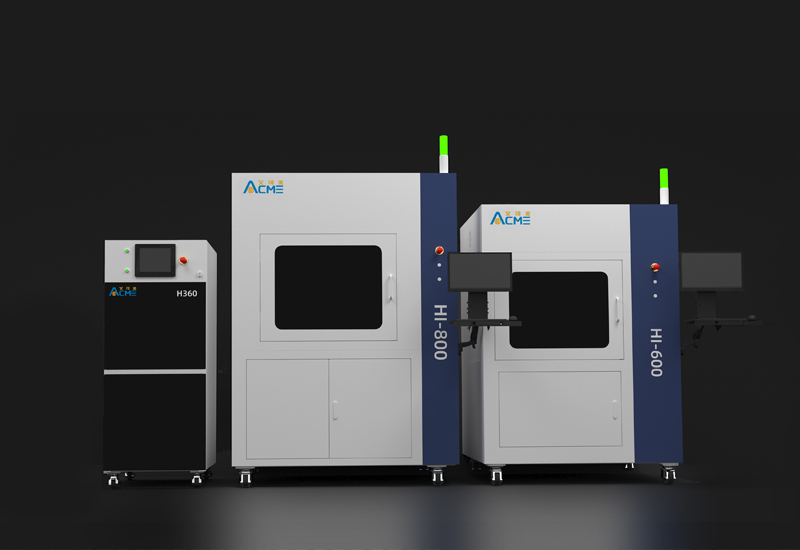

3D printer brand recommendation

Acme company focuses on the R&D, manufacturing and industrial application solutions of 3D printing equipment; focuses on the construction of modern, intelligent and digital industrial manufacturing scenes for 3D printing; focuses on the R&D and process development of technical equipment in 3D printing related fields. From the research and development, production and sales of 3D printing equipment, printing consumables and customized products, it has realized the vertical layout of the whole industrial chain.