With the development of pan-quadratic, the domestic mobile industry is developing rapidly. Especially among the young generation, mobile products with animation game IP as the core are favored. The traditional manual manufacturing is mainly manual manufacturing, and the whole manufacturing process has to go through a series of complex processes, which has high requirements on the prototype designers and tests their own technology, patience and experience. Thus created the traditional hand high price, some enthusiasts can not afford the reality. The 3D printer has replaced manual production with digital engraving. At present, 3D printing technology has been applied to manual production, which simplifies the whole process of manual model making, shortens the production cycle, saves the cost, and makes the structure proportion of the model more accurate, and 100% restores the similarity of the characters. Many handwork manufacturers and guys who love handwork want to find a suitable handwork 3D printer, so what type of 3D printer is better for handwork production? Do you have any good recommendations?

SLA print light cure hand model

Hand do 3D printer recommendation

At present, there are two kinds of mainstream hand plate 3D printer on the market: one is

Light curing 3D printer

, such as SLA photocurable 3D printer, LCD photocurable 3D printer, the production material is photosensitive resin; The other is FDM fused accumulation 3D printer, the production material is PLA, etc. As far as printing materials are concerned: compared with other materials, photosensitive resin has high molding accuracy, good appearance, fast curing, easy to support, affordable and many other characteristics, its printing effect is good, the details are strong. For the production of hand-made models, the accuracy of FDM fusion accumulation 3D printing process may not meet the requirements, while the high resolution FDM fusion accumulation 3D printer can achieve better results, but the price is too expensive. Light curing with fine molding and low price is a more suitable choice for 3D printing hand-made models. Let's take a look at what kinds of 3D printers are available.

How to choose photocuring 3D printer?

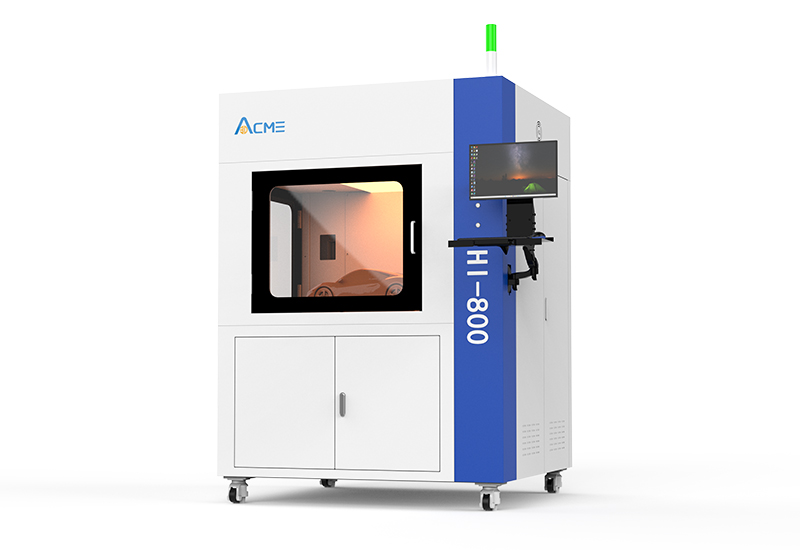

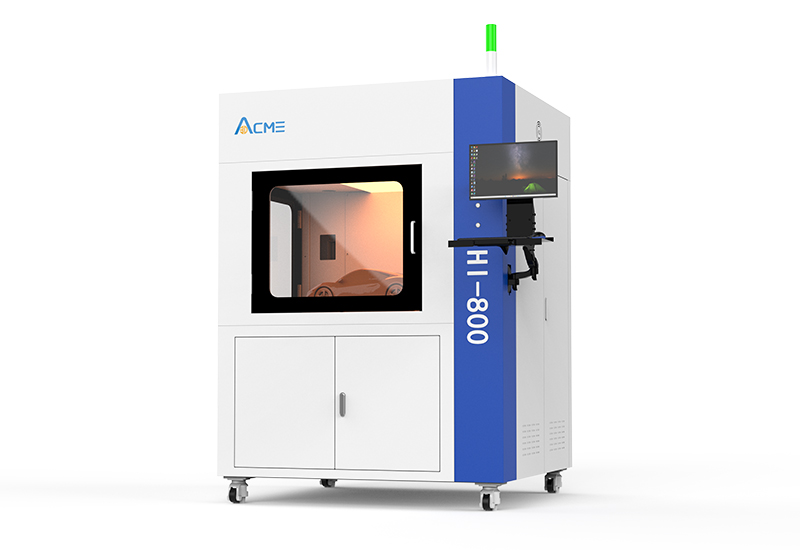

1. SLA light curing 3D printer.

The basic principle of SLA molding is to use UV laser as a light source, and then use a vibrating mirror system to control laser spot scanning. The laser beam first draws the shape of the object on the surface of the liquid resin, then the printing platform is lowered a certain distance, then the platform is soaked in the liquid resin, repeatedly forming a physical print. The size of SLA light curing 3D printer is generally large, which can realize mass printing. In terms of price, more than one hundred thousand are needed. At present, it is mainly used by hand factories, and individual players are not recommended to start.

Two, DLP light curing 3D printer.

The basic principle of DLP molding, first, the model will be cut horizontally into a layer by 3D printing software, then the projector will project the shape of the first layer model onto the resin, and then the light curing molding, the first layer molding, the object is slightly raised, the shape of the next layer model projected onto the resin, and so on, the model is printed in layers.

Three, LCD light curing 3D printer.

In fact, the principle of LCD is similar to DLP, but the light source of DLP is LCD instead. It is the imaging principle of LCD liquid crystal plate red, green, blue filter infrared and ultraviolet (infrared and ultraviolet have certain damage to the LCD), and then through the three LCD plate projection of primary colors, synthetic projection imaging.

Four, three technology comparison.

Molding speed: DLP> LCD> SLA.

Printing accuracy: DLP> SLA> LCD> FDM.

Print size range: SLA> DLP> LCD.

Material range :(DLP≠LCD)> SLA.

Service life of main components: DLP≠SLA> LCD.

Machine price: SLA> DLP> LCD.

Consumable price: SLA≠DLP≠LCD.

Through the comparison of three kinds of light curing 3D printers, I believe that we all know how to choose the right hand 3D printer.