What are the advantages and disadvantages of LCD 3D printers using LCD technology?

In the current market, the mainstream technologies used by the UV curing 3D printer are SLA, DLP and LCD. SLA is the 3D printing technology with the longest technological precipitation. DLP has high accuracy and speed but is expensive. Among the three technologies, LCD is the most common technology in the market, with a high cost performance ratio. In this article, Piocreat will briefly introduce the advantages and disadvantages of LCD light curing 3D printer, so that you can have a better goal when selecting equipment.

1、 Advantages:

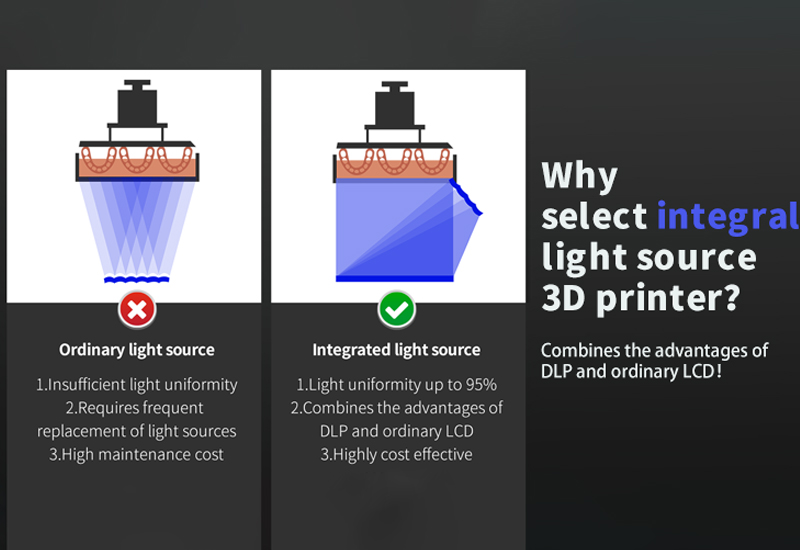

1. The LCD light curing 3D printer has high printing accuracy. Generally, it uses a transparent screen with a resolution of 4K or even 8K, which can easily reach the accuracy of 100 microns, and is technically superior to SLA technology. As far as the current situation is concerned, if it is not at the industrial level, only DLP is likely to compare with LCD in accuracy.

2. The price is cheap. The LCD uses open source technology. The components on the device are much cheaper than SLA and DLP as a whole. At present, it is the most cost-effective UV curing 3D printer.

3. Easy to use and maintain. There is no projection module like SLA laser galvo or DLP. LCD can be assembled with only one high-resolution transparent screen and Z-axis module, with simple structure and easy maintenance.

4. The consumables are universal, and the LCD screen uses 405mm ultraviolet light. Theoretically, like DLP technology, the consumable resin used is basically compatible and universal. In addition to the resin consumables dedicated to SLA, when using the LCD light curing 3D printer, do not worry about the difficulty of purchasing the corresponding consumables.

5. Fast printing speed. Compared with SLA, it is different from point formation. LCD and DLP are surface formed. No matter how many objects are printed, they are printed at the same time, and the corresponding printing speed will increase a lot.

2、 Disadvantages:

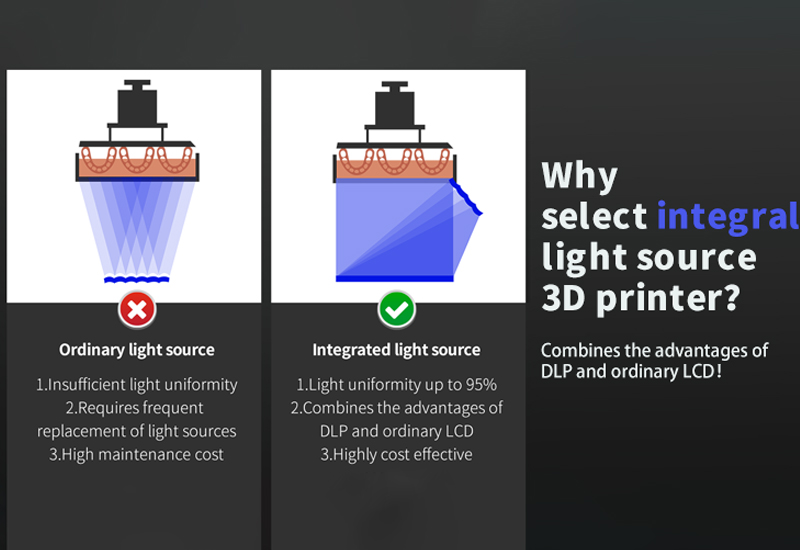

1. LCD as a key component: transparent screen has low selectivity; At present, the transparent LCD screen must have good transparency to the 405 light source, and at the same time, it needs to endure several hours of high temperature baking. Therefore, the transparent screen is the most frequently replaced part of all components of the LCD light curing 3D printer.

2. The overall print size of the LCD screen is small. Generally, the print size of the LCD screen is 192 * 120mm or 288 * 162 mm. Compared with the FDM or industrial LCD 3D printer, the overall print size of the LCD screen is small.