Recently, I have seen a lot of news. Jewelry can be printed in 3D. It's incredible! But at the same time, we are also curious: what is the development prospect of jewelry 3D printers in the jewelry industry, and what are their advantages?

Jewelry 3D printing technology refers to the use of jewelry 3D printers to manufacture jewelry products, which can produce high-precision and high-quality jewelry in a relatively short time. At present, jewelry 3D printing technology has been widely used in the jewelry industry, and with the continuous progress of technology and cost reduction, its development prospects are also very broad.

The following are the development prospects of jewelry 3D printing technology in the jewelry industry:

1: More freedom of design: jewelry 3D printing technology can achieve more freedom of jewelry design without being limited by traditional manufacturing technology. Designers can use 3D modeling software to design and manufacture complex shapes and structures, and can also customize according to customers' needs, which will bring more diversified products to the jewelry industry.

2: Save time and cost: traditional jewelry manufacturing needs to make molds, which will consume a lot of time and cost. Jewelry 3D printing technology can directly manufacture jewelry products through 3D printers, greatly reducing the manufacturing cycle and manufacturing costs.

3: Improve production efficiency: Jewelry 3D printing technology can realize automatic production and greatly improve production efficiency. The 3D printer for manufacturing jewelry products can work without interruption, reducing human resources and production costs.

4: Break the traditional manufacturing mode: jewelry 3D printing technology can reduce human factors in jewelry manufacturing through digital production, and also make the manufacturing process of jewelry industry more transparent and intelligent.

5: Improve quality and precision: Traditional jewelry manufacturing often requires multiple processing and carving to achieve ideal quality and precision. Jewelry 3D printing technology can directly produce high-quality jewelry products through high-precision jewelry 3D printers, reducing human interference and error.

In short, the development of jewelry 3D printers will bring more diversified, high-quality and efficient products to the jewelry industry, as well as more business opportunities and market opportunities.

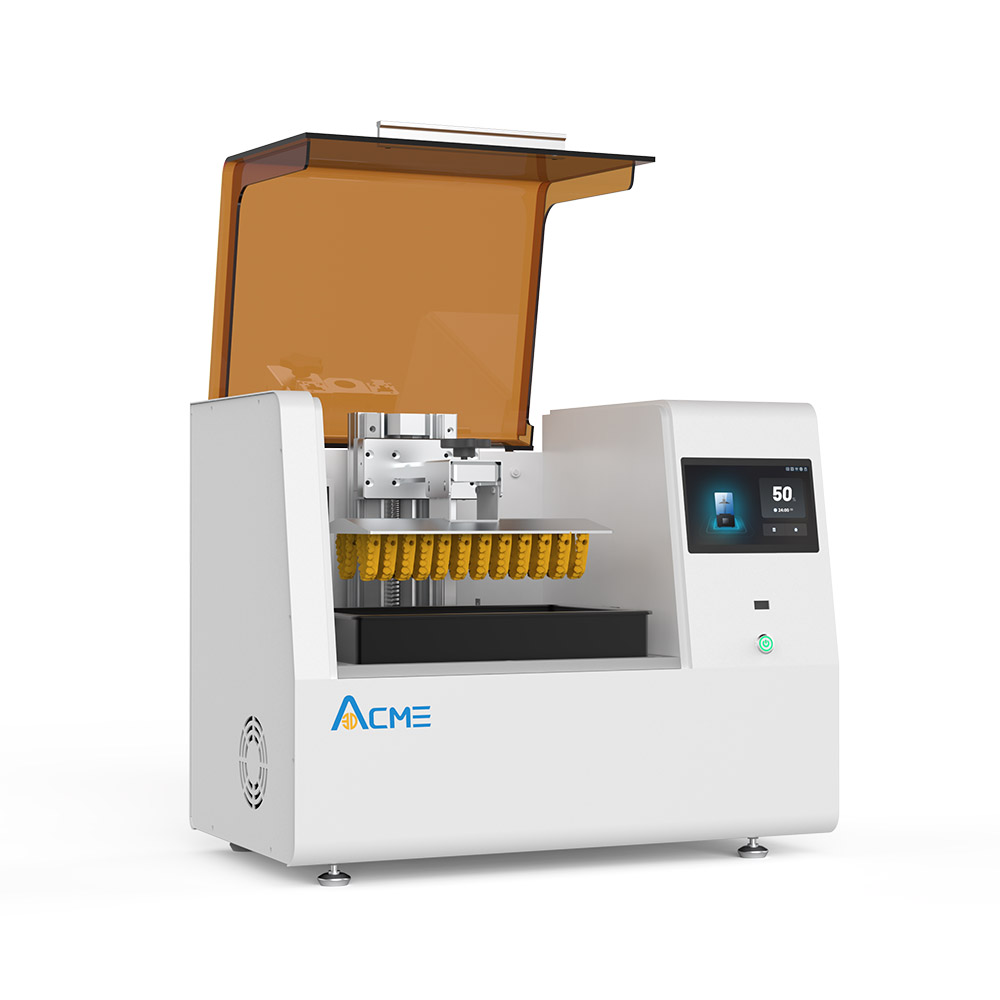

Hagong 3D also has certain development and market share in the jewelry 3D printer industry. The HI 600 and HI 800 jewelry 3D printers launched by the company are specially designed for the jewelry industry, with high accuracy, high speed, high reliability and other characteristics. Among them, the minimum manufacturing accuracy of the HI 800 jewelry 3D printer can reach 0.01mm, which can produce very fine jewelry models and samples. The HI 600 jewelry 3D printer has a larger manufacturing size and higher manufacturing efficiency, which can meet the needs of mass and high-quality production.

In addition, Hagong 3D also provided corresponding 3D printing solutions and technical support to help customers realize the digital production of 3D printing for jewelry. The company's customers in the jewelry industry include some well-known jewelry brands and manufacturers, and have gained a certain reputation and market share in the domestic and foreign markets.

In general, HG3D has performed well in the jewelry 3D printer industry, has certain technical strength and market competitiveness, and has certain development prospects.

+86 19958086067

sales@3dacme.com