The application of 3D printing technology in the field of dentistry has been widely used. Compared with traditional manual production, dental 3D printers can greatly shorten production time, improve precision and quality, and save costs at the same time. In addition,

dental 3D printers can also be combined with oral scanners to realize a digital oral impression production process, further improving production efficiency and accuracy.

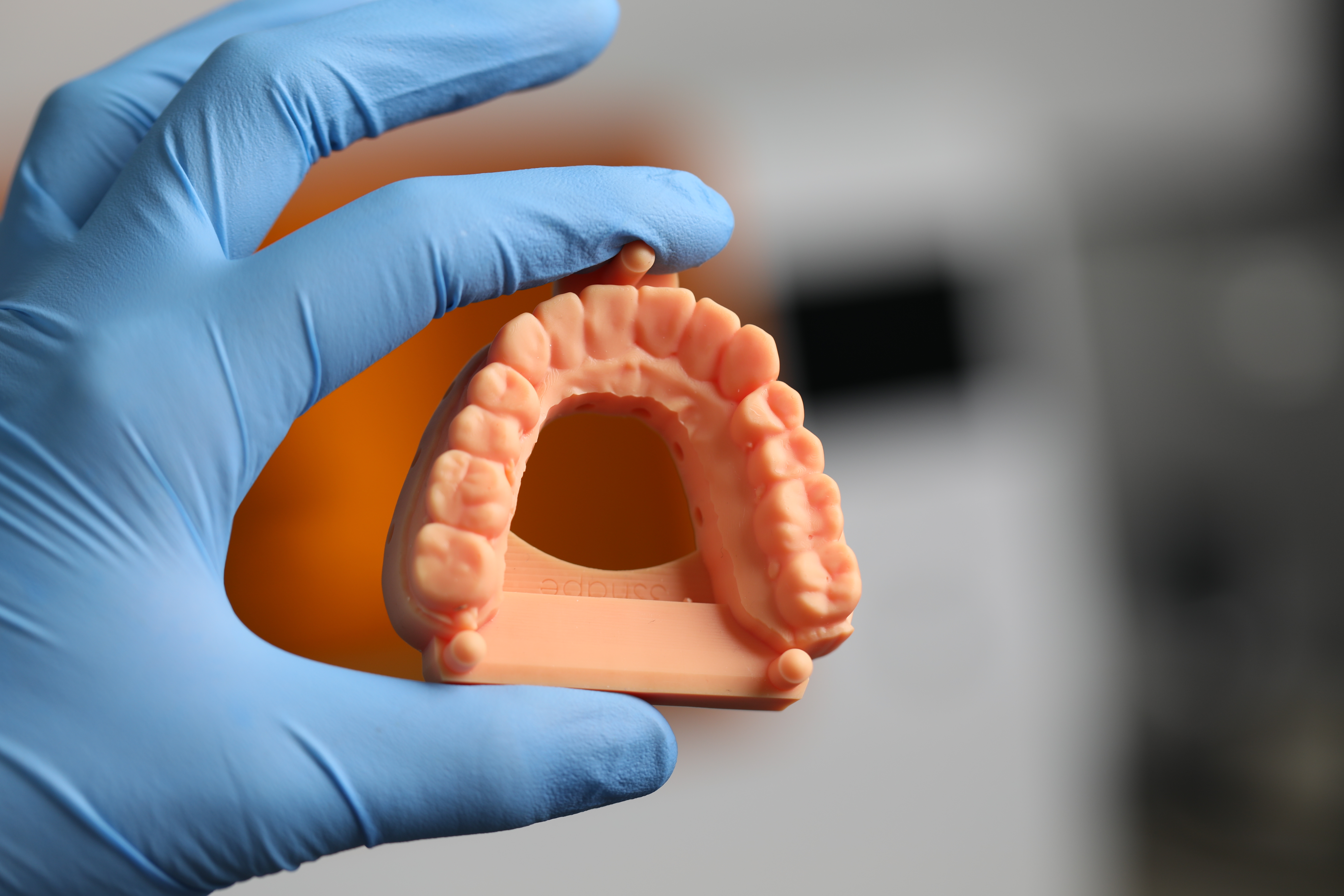

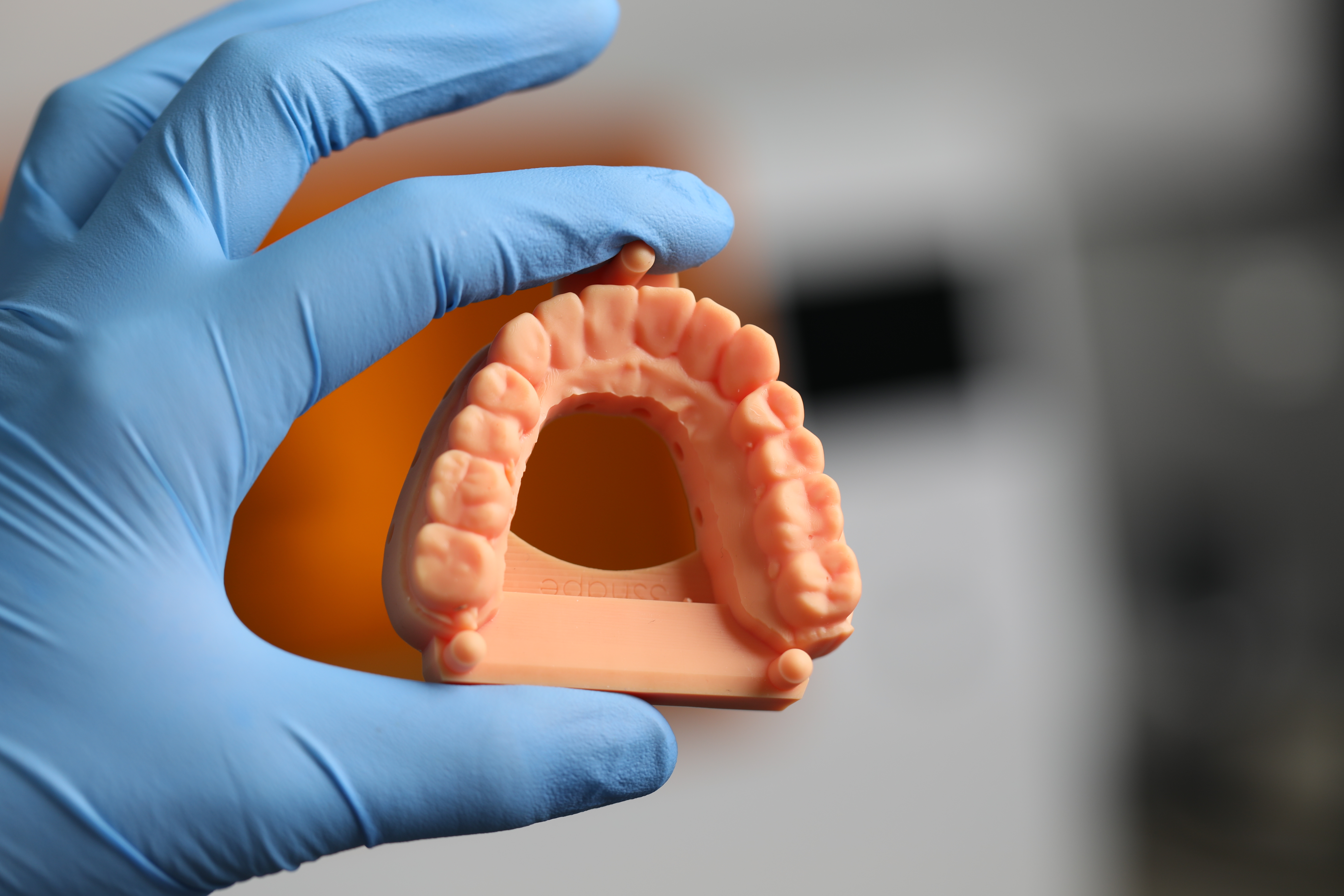

Through 3D printing technology, high-precision and high-quality dental models can be produced, avoiding errors and deficiencies in manual production. At the same time, 3D printing technology can also realize personalized customization, and carry out precise design and production according to the actual situation of the patient's oral cavity, so as to improve the treatment effect and success rate.

The application of 3D printing technology in dental surgery has been widely used, and its main role is to help doctors perform dental implant and restoration operations more accurately. Specifically, 3D printing technology can be applied in the following fields:

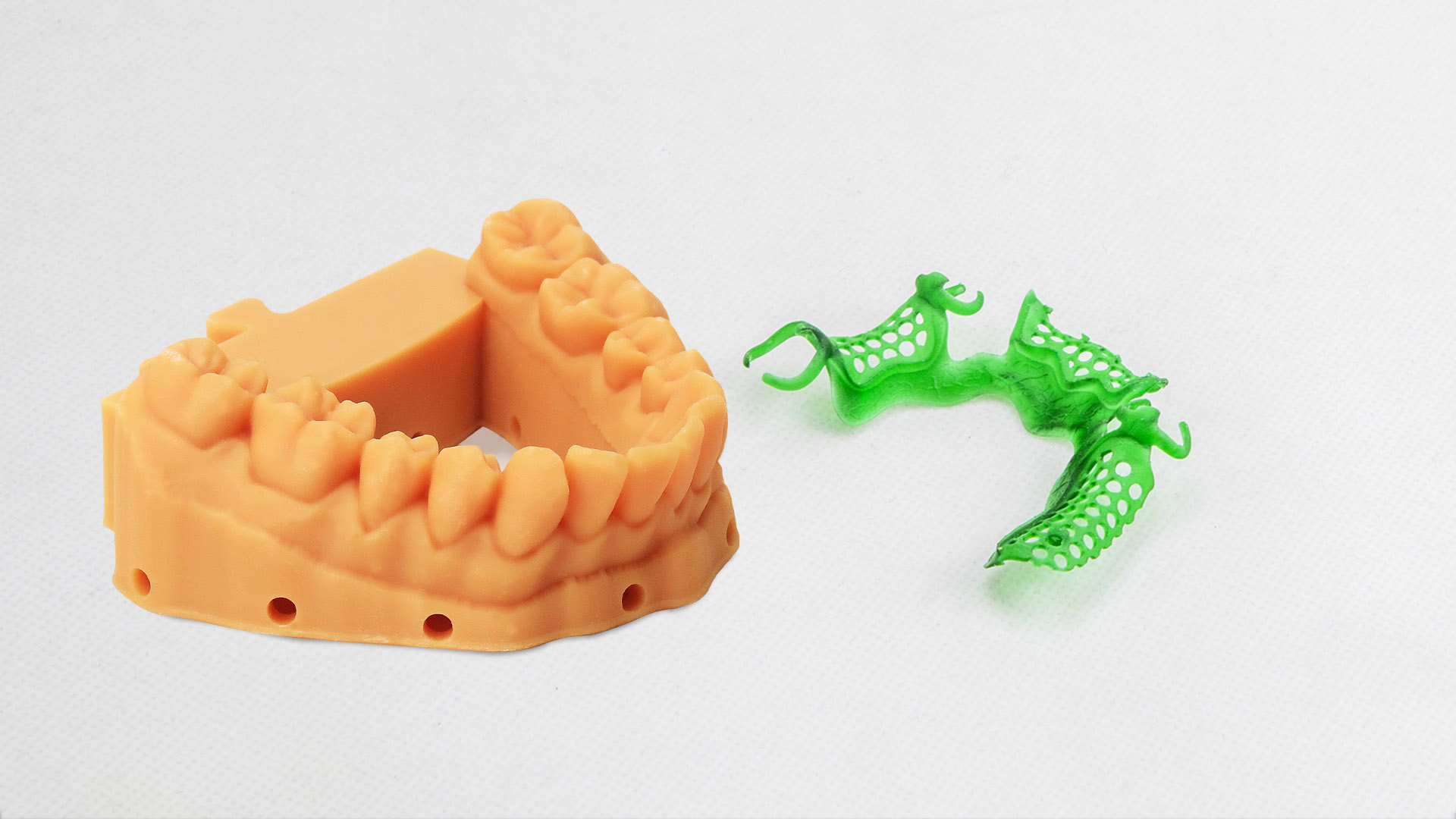

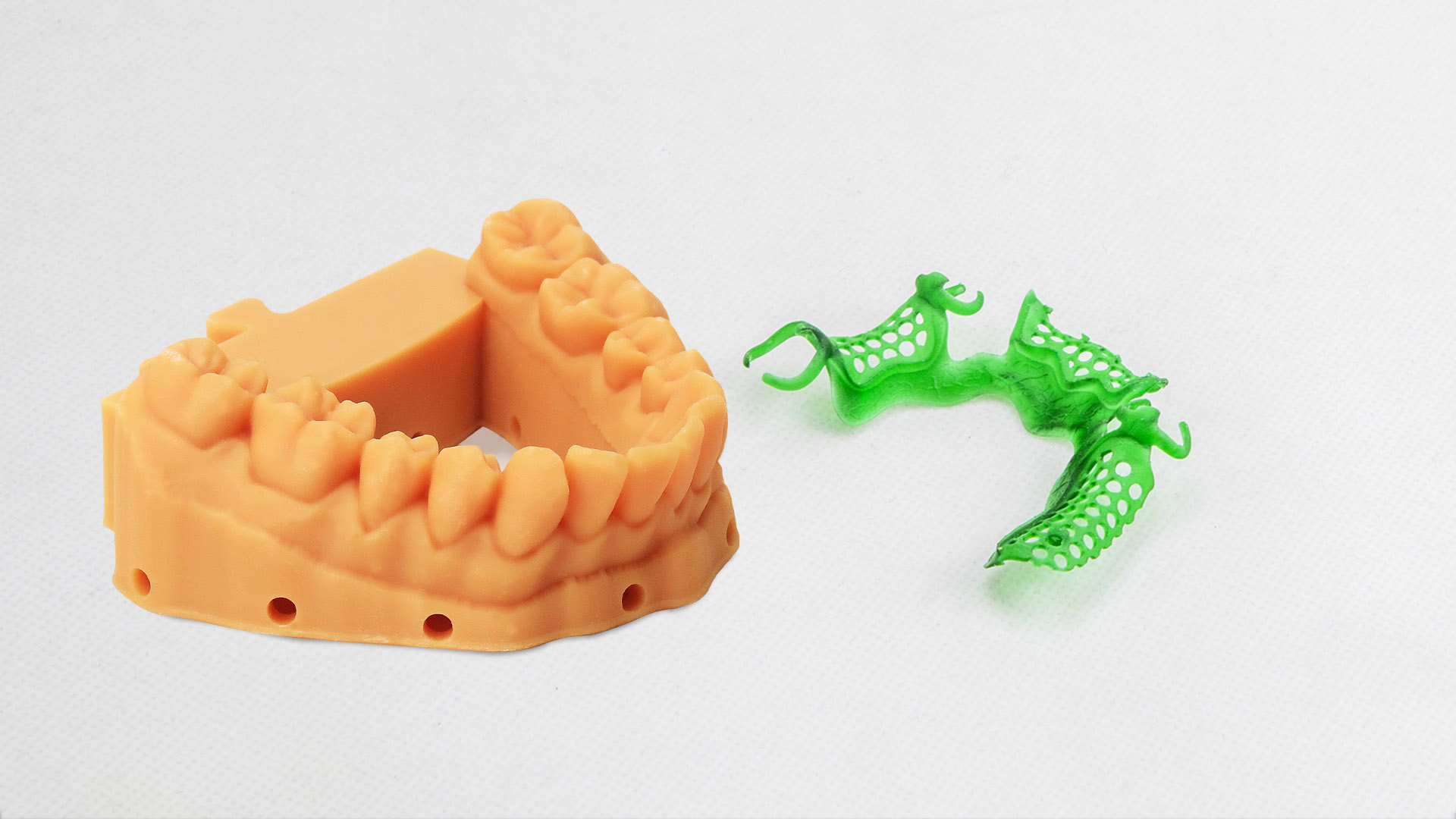

Cast dental model:The application of 3D printing technology in dental mold casting has been widely used. Traditional dental mold casting needs to be manually made and adjusted, which is time-consuming and labor-intensive. With 3D printing technology, digital scanning can be carried out in the patient's mouth to generate a three-dimensional model of the patient's mouth, and on this basis, the design and production of dental mold casting can be carried out.

Through 3D printing technology, high-precision and high-quality dental models can be produced, avoiding errors and deficiencies in manual production. At the same time, 3D printing technology can also realize personalized customization, and carry out precise design and production according to the actual situation of the patient's oral cavity, so as to improve the treatment effect and success rate.

In dental mold casting, 3D printing technology can also realize digital design and production, which saves a lot of labor and time costs in traditional processes, reduces the interference of human factors, and improves production efficiency and quality. In addition, dental models made with 3D printing technology can also be quickly made and modified to meet various treatment needs and individual requirements.

Therefore, the application of 3D printing technology in dental mold casting can help dentists improve the treatment effect and success rate, as well as improve production efficiency and quality, realize digital manufacturing and personalized customization, and further promote the development and innovation of the dental industry.

Temporary Crowns:

Temporary Crowns:The application of 3D printing technology in dental temporary crowns has been widely used. A temporary crown is a temporary restoration used to restore a tooth and usually needs to be customized and installed in the patient's mouth to ensure that the patient can eat and speak normally while the formal restoration is in place.

The traditional temporary crown production requires many times of manual production and adjustment, which is time-consuming and labor-intensive. With 3D printing technology, digital scanning can be carried out in the patient's mouth to generate a three-dimensional model of the patient's mouth, and on this basis, the design and production of temporary crowns can be carried out. Since 3D printing technology has the characteristics of high precision, high efficiency and high reliability, it can greatly reduce production time and manual errors, and at the same time, it can realize personalized customization and improve patient comfort and treatment effect.

In addition, temporary dental crowns made with 3D printing technology can also help doctors evaluate and plan treatment plans more accurately, achieve refined treatment, and improve treatment effects and success rates.

Therefore, the application of 3D printing technology in dental temporary crowns can help doctors improve the treatment effect and success rate, while also improving patient comfort and treatment experience.

Surgical Guide:

Surgical Guide:The application of 3D printing technology in dental surgery guides has been widely used, and its main role is to help doctors perform dental implant and restoration operations more accurately. Specifically, 3D printing technology can achieve the following functions:

Make precise tooth models: 3D printing technology can make tooth models with high precision, helping doctors to evaluate and plan surgery more accurately.

Production of surgical guides: 3D printing technology can produce surgical guides that conform to the characteristics of the patient's mouth, enabling doctors to perform dental implants and restorations more accurately during the operation.

Shorten the operation time: Thanks to the existence of the surgical guide, the doctor can perform the operation more quickly, thereby shortening the operation time and reducing the pain and discomfort of the patient.

Reduce the risk of surgery: The surgical guide can effectively reduce the risk of surgery and avoid mistakes or accidental injury to surrounding tissues during surgery.

To sum up, the application of 3D printing technology in dental surgery guides can help doctors perform surgery more accurately, improve the efficiency and success rate of surgery, and reduce the pain and discomfort of patients.

Orthodontic model:

Orthodontic model:The application of 3D printing technology in dental orthodontic restoration has been widely used, mainly in the production of aligners and braces.

Traditional aligners and braces need to be handmade and require multiple follow-up visits for fine-tuning and adjustments, a lengthy and cumbersome process. With 3D printing technology, doctors only need to perform a digital scan in the patient's mouth to generate a three-dimensional model of the patient's mouth, and then design and manufacture aligners and braces on this basis. Since 3D printing technology has the characteristics of high precision, high efficiency and high reliability, it can greatly reduce production time and manual errors, and at the same time, it can realize personalized customization and improve patient comfort and treatment effect.

In addition, aligners and braces made with 3D printing technology can also help doctors evaluate and plan treatment plans more accurately, achieve refined treatment, and improve treatment effects and success rates.

Therefore, the application of 3D printing technology in dental orthodontic restoration can help doctors improve the treatment effect and success rate, and at the same time improve the comfort and treatment experience of patients.

In the field of dentistry, 3D printing technology can also realize digital design and production, which saves a lot of labor and time costs in traditional processes, reduces the interference of human factors, and improves production efficiency and quality. In addition, dental models made with 3D printing technology can also be quickly made and modified to meet various treatment needs and individual requirements.

Therefore, the application of 3D printing technology in the field of dentistry can help dentists improve the treatment effect and success rate, and at the same time improve production efficiency and quality, realize digital manufacturing and personalized customization, and further promote the development and innovation of the dental industry.

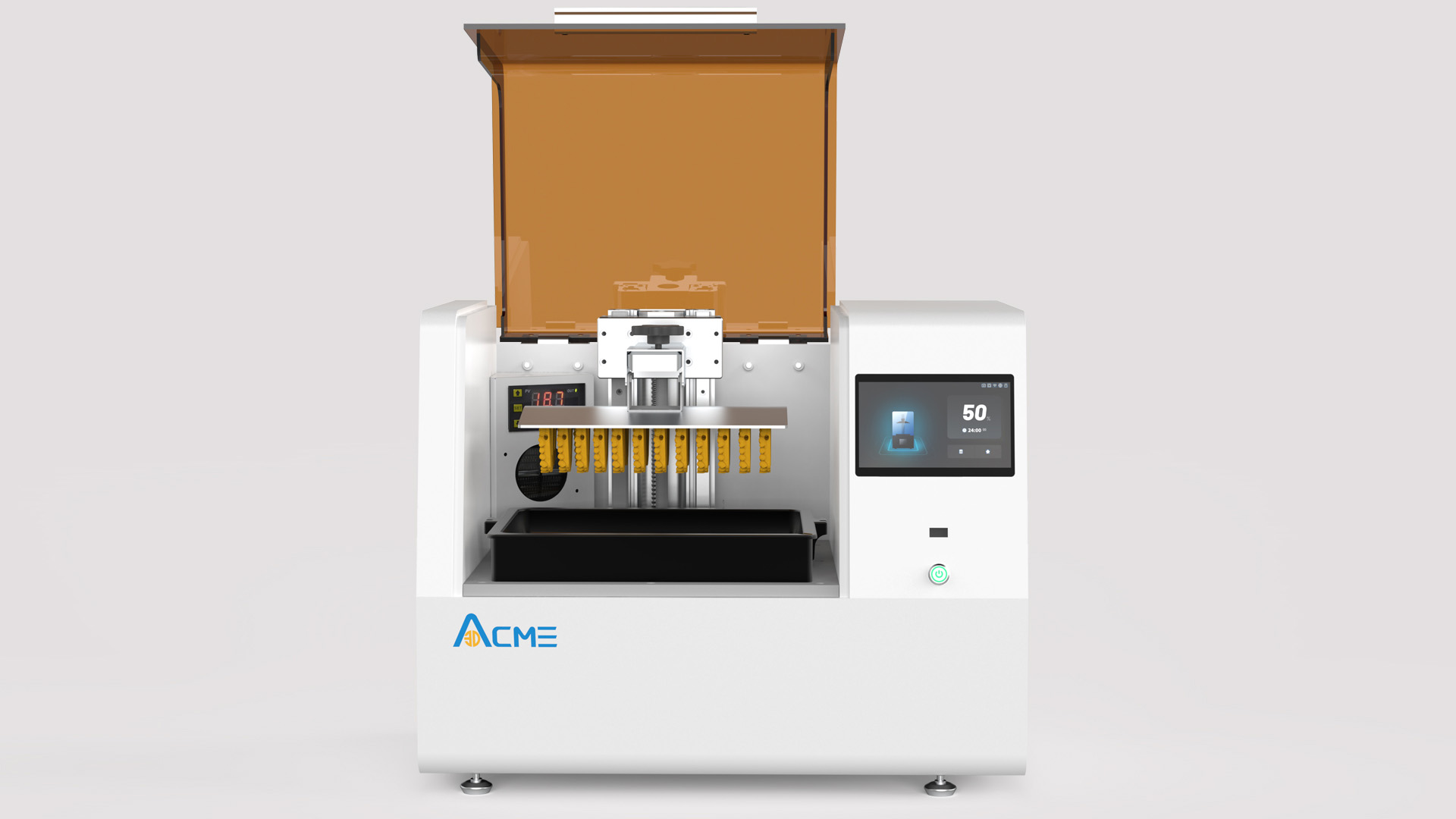

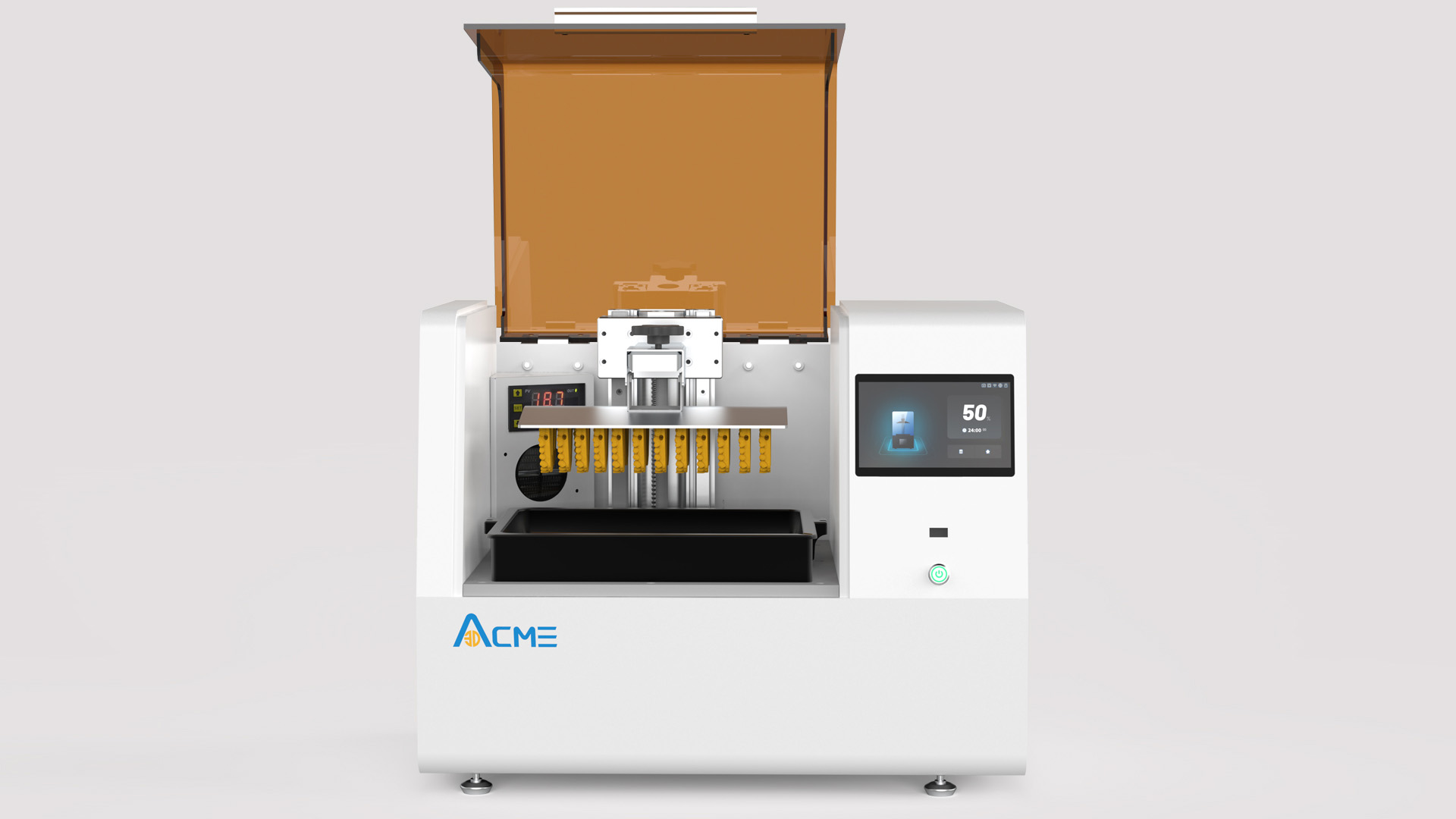

ACME R3pro

dental 3D printer is mainly used in the field of dentistry. With 8K high-precision resolution, 10.1-inch printing format, and multi-material applicability, it can provide better 3D printing solutions for dentists and technicians.

In the dental industry, 3D printing technology can be used to manufacture customized orthodontic models, temporary crowns, cast crowns, surgical guides and other models. By using 3D printing technology, production time and cost can be greatly reduced, and production efficiency and quality can be improved. At the same time, the use of 3D printing technology can reduce the dependence on traditional manufacturing processes, making the dental industry more flexible and innovative.

To sum up, the application of 3D printing technology in the field of dentistry can help dentists improve the treatment effect and success rate, and at the same time improve production efficiency and quality, realize digital manufacturing and personalized customization, and further promote the development and innovation of the dental industry .