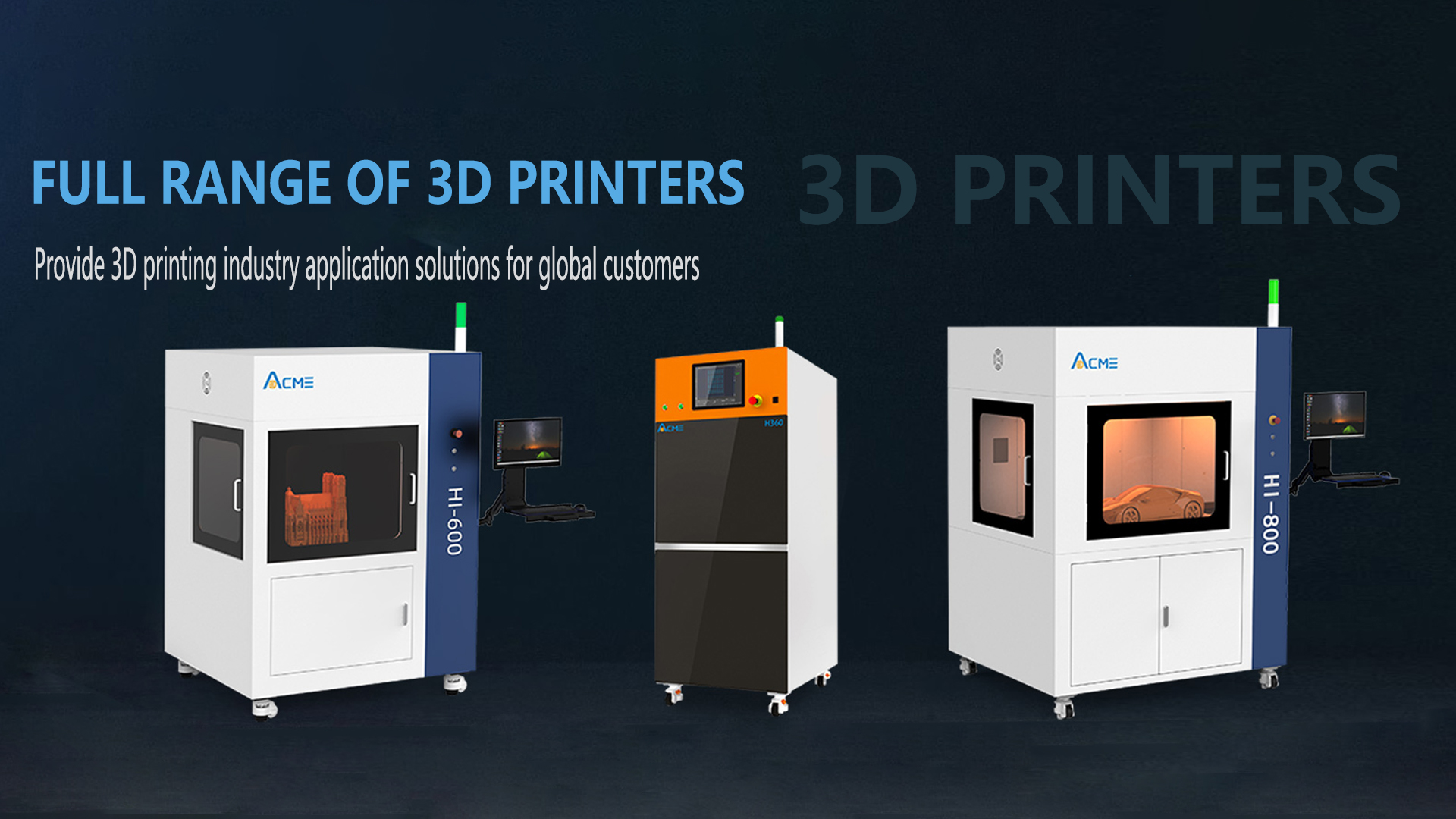

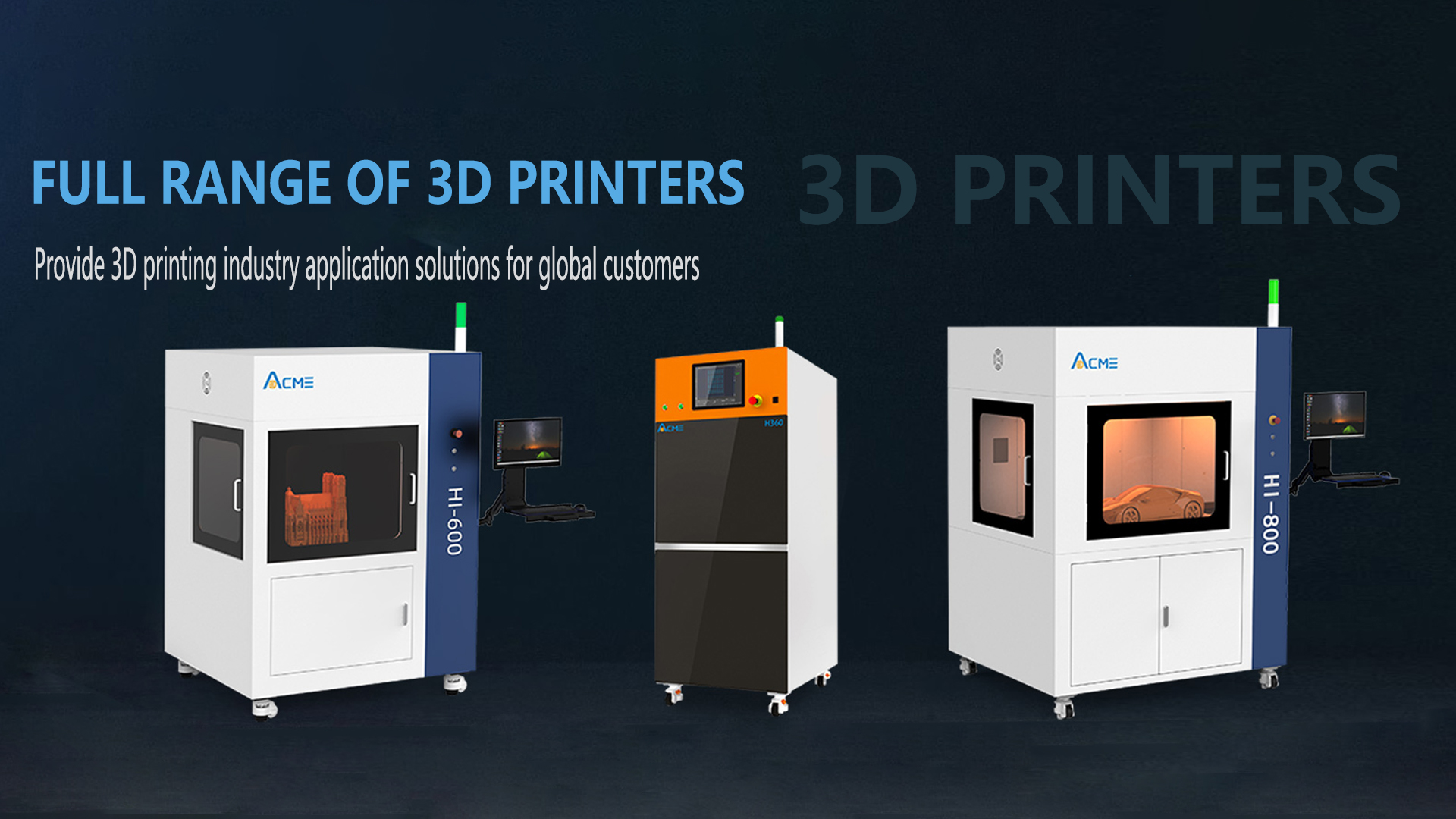

In recent years, the industrial manufacturing landscape has witnessed a groundbreaking technological advancement –

SLA 3D printing. This cutting-edge additive manufacturing technique has revolutionized the way industries produce complex and high-quality parts. In this article, we will explore the power of SLA 3D printers and their transformative impact on industrial manufacturing processes.

Understanding SLA 3D Printing:

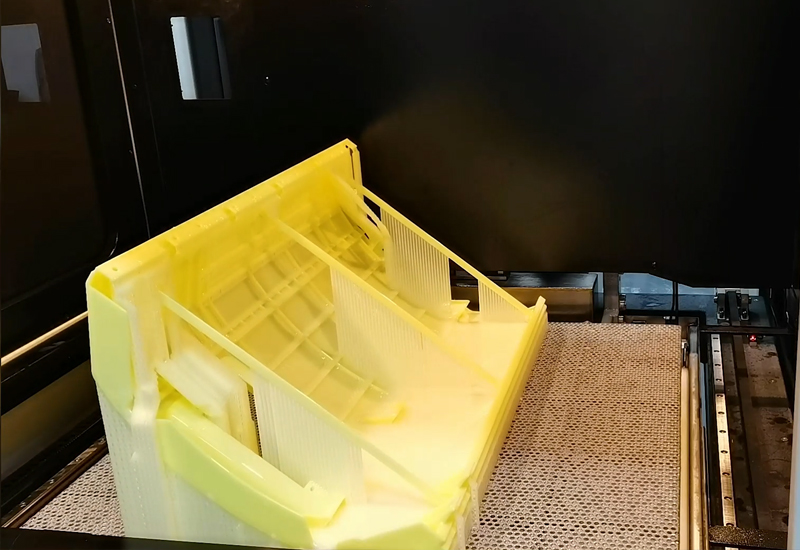

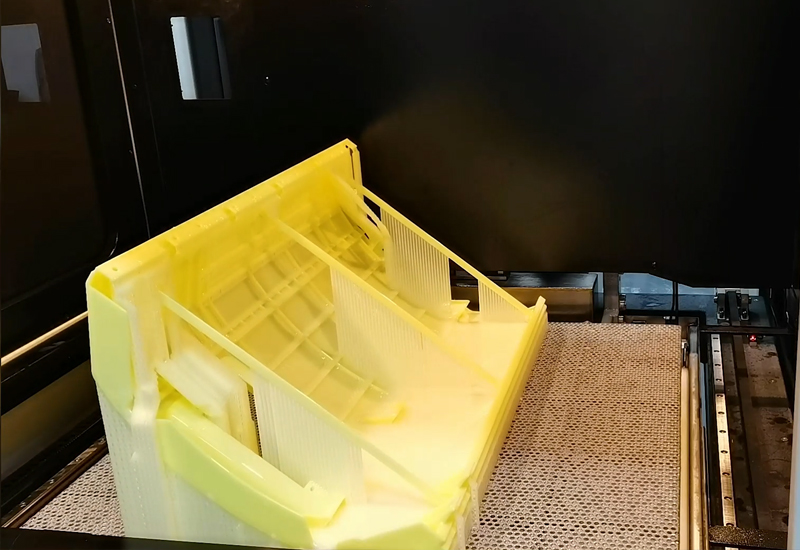

Understanding SLA 3D Printing:SLA, or Stereolithography, is a 3D printing technology that utilizes liquid photopolymer resins to create highly detailed and precise three-dimensional objects. It employs a process called photopolymerization, where a laser selectively cures the resin layer by layer, solidifying it into the desired shape. This layer-by-layer approach allows for intricate geometries and exceptional surface finishes, making SLA 3D printing an ideal choice for industrial applications.

Unparalleled Precision and Complexity:One of the key advantages of SLA 3D printing in industrial manufacturing is its ability to produce parts with unparalleled precision and complexity. The high-resolution laser systems in SLA printers can achieve layer thicknesses as low as 25 microns, resulting in parts with intricate details and fine features. This level of precision allows industries to manufacture parts with tight tolerances and intricate geometries that were previously unachievable through traditional manufacturing methods.

Rapid Prototyping and Iteration:SLA 3D printing enables rapid prototyping, allowing industries to bring their ideas to life quickly and efficiently. With the ability to produce functional prototypes within hours, designers and engineers can iterate designs, test form and fit, and make necessary modifications on the fly. This iterative approach significantly accelerates the product development cycle, reducing time-to-market and providing a competitive edge to manufacturers.

Cost-Efficiency and Customization:SLA 3D printing offers cost-efficiency advantages over traditional manufacturing methods, particularly for low-volume production or customized parts. Traditional manufacturing often involves expensive tooling and setup costs, which can be prohibitive for small production runs. SLA 3D printing eliminates the need for costly tooling, making it economically viable even for small batch production. Additionally, the ability to customize each part individually opens up new opportunities for tailored products and personalized solutions.

Diverse Range of Materials:SLA 3D printing provides access to a wide range of advanced materials suitable for industrial applications. From tough engineering resins to high-temperature and biocompatible materials, industries can choose from a diverse palette of materials that meet their specific requirements. These materials exhibit excellent mechanical properties, chemical resistance, and heat tolerance, making them ideal for manufacturing functional end-use parts.

Streamlined Production Processes:Integrating SLA 3D printing into industrial manufacturing workflows streamlines production processes and enhances operational efficiency. With reduced dependence on traditional manufacturing methods, manufacturers can optimize their supply chains, minimize inventory costs, and respond quickly to market demands. This flexibility and agility empower industries to stay ahead of the competition in today's dynamic business landscape.

SLA 3D printing

SLA 3D printing has emerged as a game-changer in industrial manufacturing, enabling precision, complexity, cost-efficiency, and customization like never before. As this technology continues to evolve, we can expect to witness further advancements in materials, printing speed, and scalability. Industries embracing SLA 3D printing are poised to unlock new possibilities, enhance productivity, and stay at the forefront of innovation in the ever-evolving world of industrial manufacturing.