There is a problem with converting the 3D printing model file to STL, how to repair the model?

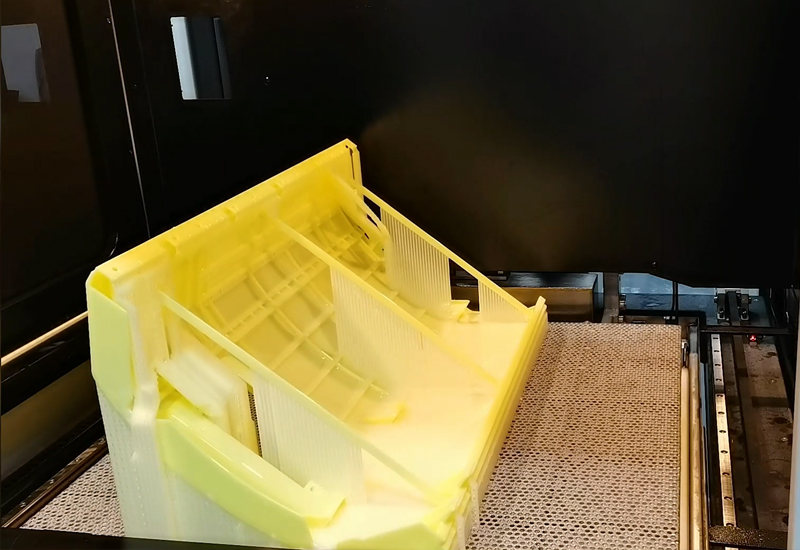

With the maturity of 3D printing technology, many companies have introduced 3D printers for product design and development. The premise of 3D printing is that the corresponding 3D model files are required. The 3D model files made by the designer may be made by different software, but the final converted ones are all in STL format. During the format conversion process, the converted model has There may be problems and it cannot meet the requirements of 3D printing. At this time, the model file needs to be repaired. There is a problem with converting the 3D printing model file to STL, how to repair the model? What are the common repair methods?

What problems are prone to occur when converting 3D printing model files into STL? What are the common repair methods?1. Wall thickness

A key factor that affects the smoothness of 3D printing is that a 3D model has no wall thickness, it is all pieces and lines, and the 3D printer will not be able to print it. Compared with 3D printing service providers, there is usually a regulation on wall thickness, which is slightly more conservative than the printing process limit, reducing the probability of objects being damaged during transportation and removal. Now it is necessary to do a good job of thickening the wall thickness.

2. Size

In many cases, the printing size was not taken into consideration when the object was first designed, which caused confusion about whether the 3D printing could be done well in the later stage. Therefore, relative to the confirmation of the size, the earlier the better, it may involve disassembly if it is too large, and the printing details may be lost if it is too small.

3. Problems in the non-manifold modeling process or some "shortcuts" or "tricks" may cause the emergence of non-manifolds. This also means that one edge is the same or multiple faces intersect, rather than a body-to-body intersection, which will make the 3D printer think that the model has holes, or at least the faces have problems and cannot be printed. Capable of filling holes.

4. The normal line is used to distinguish the inner and outer planes, which is very important for the printer. If the normal line is reversed, the 3D printer cannot recognize the boundaries of the model. Need to do a good job of model normal repair.

5. Intersecting overlapping surfaces will cause overlapping volumes, resulting in inaccurate volume calculations and overcalculated volumes. In addition, it will also cause problems with the orientation of the positioning surface, so the overlapping overlapping surfaces must be well merged.

6. The minimum gap refers to the minimum distance between two wall thicknesses, which is related to the physical limit of the 3D printer. If the minimum gap is lower than the printing limit of 3D printing, the two walls will merge into one wall thickness, which will cause some supports or residues to not come out.

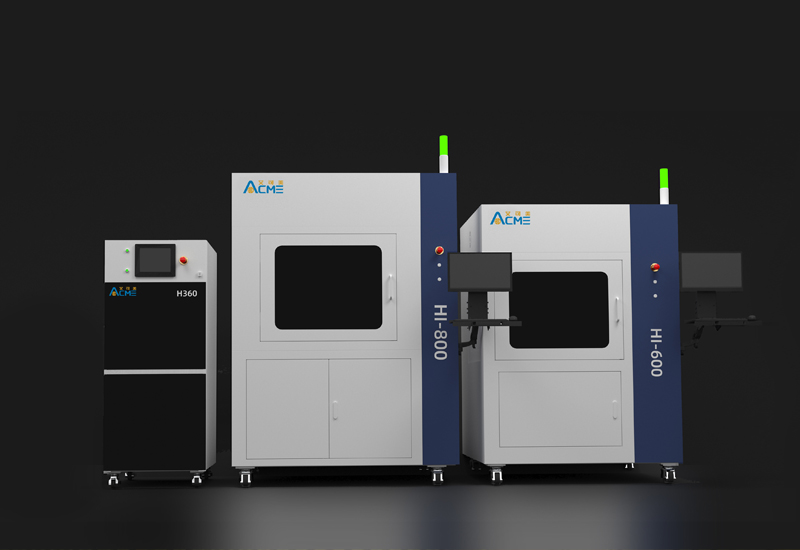

The above are some collected and sorted by Harbin Engineering 3D editor. The 3D printing model file is converted into STL repair method. At present, there are some software with automatic repair function in the market. Later, the editor will sort out some for your reference and study. Acme 3d is a professional 3D printer developer and manufacturer in China, focusing on the development and comprehensive application of 3D printing technology. Harbin Engineering 3D integrates R&D, production, marketing and service, and is committed to building a 3D printing digital ecosystem. Its business areas cover 3D printers, 3D scanners, 3D printing consumables (light-curing resin), 3D scanners, and 3D printing integration. Services, etc., products are exported to all over the world.